Improving the productivity of ultra-fine powder grinding mills requires a holistic approach that addresses precision engineering, enhanced grinding mechanisms, intelligent process control systems, and advanced material handling and air filtration. By embracing these strategies, manufacturers can unlock new levels of efficiency, produce superior quality powders, and stay at the forefront of their respective industries.

24 Online Service

In the realm of material processing and particle size reduction, the concept of ultrafine grinding has emerged as a crucial technique. With the advancement of technology and the increasing demand for finer particles in various industries, ultrafine grinding has gained significant attention and importance.

Ultrafine grinding, also known as ultrafine milling or ultrafine comminution, refers to the process of reducing materials to extremely small particle sizes, typically in the range of nanometers or micrometers. While traditional grinding techniques can achieve particle sizes in the micron range, ultrafine grinding pushes the boundaries by enabling the production of particles that are much smaller, thus offering unique properties and enhanced performance.

One of the main reasons for pursuing ultrafine grinding is the desire to overcome the limitations of conventional grinding methods. In many industries such as pharmaceuticals, cosmetics, chemicals, and materials science, the properties and performance of materials are strongly influenced by particle size. By reducing particle size to the ultrafine range, it becomes possible to unlock new functionalities, improve solubility, increase surface area, enhance reactivity, and modify mechanical and optical properties.

There are various techniques employed in ultrafine grinding, each with its own advantages and limitations. One of the most commonly used methods is mechanical grinding, which involves the use of mechanical forces such as impact, compression, and attrition to break down particles. This can be achieved using equipment such as ball mills, jet mills, and stirred media mills. Mechanical grinding offers versatility, scalability, and the ability to process a wide range of materials.

Another popular approach to ultrafine grinding is through the use of fluid energy mills, such as jet mills and fluidized bed jet mills. These mills utilize high-velocity jets of compressed gas or steam to cause particle size reduction through collision and attrition. Fluid energy mills are particularly suitable for grinding heat-sensitive and friable materials, as they operate at lower temperatures compared to mechanical mills.

In recent years, advancements in nanotechnology have led to the development of novel techniques for ultrafine grinding. For instance, the use of nanomaterials as grinding media in bead mills has gained attention. These nanomaterials possess unique properties such as high hardness, wear resistance, and tailored surface chemistry, enabling efficient grinding of materials to the nanoscale. Additionally, techniques like high-pressure homogenization and electrospinning have also been explored for achieving ultrafine particle sizes.

The applications of ultrafine grinding are extensive and span across numerous industries. In the pharmaceutical field, ultrafine grinding is employed to improve the dissolution rates and bioavailability of poorly water-soluble drugs. The cosmetic industry utilizes ultrafine grinding to enhance the performance of pigments, sunscreen agents, and other active ingredients. In the materials science domain, ultrafine grinding enables the production of nanoparticles for catalysis, energy storage, and advanced coatings.

While the benefits of ultrafine grinding are compelling, it is essential to consider the challenges associated with this technique. Achieving and maintaining the desired particle size distribution can be complex and require careful control of process parameters. Moreover, the cost of equipment and energy consumption may be higher compared to conventional grinding methods. It is also crucial to ensure the safety of operators and minimize the generation of airborne particles during the grinding process.

In the realm of materials processing and particle size reduction, advancements in technology have led to the development of cutting-edge equipment capable of achieving ultrafine grinding. Among these innovative solutions, the ultrafine grinding mill stands out as a revolutionary tool that has revolutionized various industries.

Particle size reduction is a fundamental process in industries such as pharmaceuticals, chemicals, minerals, and food processing, where finely ground materials are required for various applications. Conventional grinding mills have been traditionally used for this purpose, but they often fall short in achieving the desired fineness. This limitation led to the emergence of ultrafine grinding mills.

An ultrafine grinding mill, also known as a superfine mill or micronizer, is a high-precision grinding machine that produces ultrafine particles. It employs mechanical and interparticle forces to break down solid materials into extremely fine powders. Unlike conventional mills, which typically achieve particle sizes in the micrometer range, ultrafine grinding mills excel in producing submicron or nanometer-sized particles.

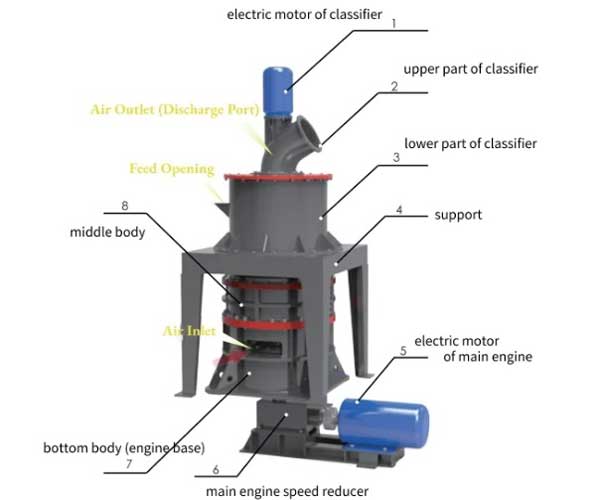

Ultrafine grinding mills utilize a combination of mechanical impact, compression, and high-speed rotation to achieve particle size reduction. The mill consists of a cylindrical chamber containing grinding media such as ceramic or metallic balls. As the mill rotates, the grinding media collide with the material, causing the particles to fracture into smaller sizes. The adjustable speed and rotation direction allow for precise control over the grinding process.

The versatility of ultrafine grinding mills enables their utilization in various industries:

In recent years, advancements in materials science and manufacturing technology have led to the development of ultrafine powder grinding mills. These state-of-the-art machines are revolutionizing various industries by providing unmatched grinding capabilities for a wide range of materials. With their ability to produce ultrafine powders, these mills have opened up new possibilities in fields such as pharmaceuticals, chemicals, minerals, and more.

The capacity of an ultrafine powder grinding mill refers to its ability to process a specific amount of material within a given time frame. The capacity varies depending on the model and design of the mill, as well as the characteristics of the material being processed. While different manufacturers offer various capacity options, modern ultrafine powder grinding mills can typically handle large volumes of materials.

The primary factors contributing to the impressive capacity of these mills are:

Ultrafine powder grinding mills are equipped with powerful motors that drive the grinding elements at high rotational speeds. This rapid motion enhances the efficiency of the grinding process, allowing for a higher throughput and increased production capacity.

These mills employ a combination of impact, shear, and attrition forces to break down the material into fine particles. By utilizing different grinding mechanisms simultaneously, ultrafine powder grinding mills can achieve higher capacities and produce consistent results.

The fineness of the final product can be finely tuned and adjusted according to specific requirements. This flexibility enables manufacturers to optimize the grinding process, ensuring maximum output without compromising on the quality of the end product.

In the realm of material processing and manufacturing, the demand for ultra-fine powders continues to rise across a wide range of industries. Ultra-fine powder grinding mills play a crucial role in meeting this demand by providing the means to efficiently grind and process materials into particles of exceptional fineness. However, as technology advances and productivity expectations increase, it becomes necessary to explore methods for further improving these mills’ performance.

The foundation of a high-productivity ultra-fine powder grinding mill lies in its precision engineering and design. The mill’s components, including the grinding chamber, rotor, and classifier, must be precisely crafted to minimize energy loss and maximize particle reduction. Attention to detail during the manufacturing process is crucial to ensure smooth operation and reduced wear. Utilizing advanced design tools, such as computer-aided design (CAD) and computational fluid dynamics (CFD) simulations, can aid in optimizing these components and improving overall mill performance.

The grinding mechanism is at the heart of any powder grinding mill. To enhance productivity, several improvements can be implemented:

Integrating intelligent process control systems can significantly improve the productivity of ultra-fine powder grinding mills. These systems employ advanced algorithms and sensors to monitor and optimize key parameters in real-time, ensuring consistent and efficient operation. Some key features of intelligent process control systems include:

By continuously monitoring the feed rate and adjusting it in response to variations, the mill can maintain a stable grinding environment, reducing downtime and improving overall productivity.

Real-time monitoring of particle size distribution enables the mill to adjust grinding conditions promptly. This feedback loop allows for tighter control over the final product quality and ensures optimal grinding efficiency.

Intelligent process control systems can identify energy-consuming operations and suggest adjustments to reduce energy consumption without compromising productivity. This results in cost savings and environmental benefits.

Efficient material handling and air filtration systems are essential for maintaining a clean and controlled environment in ultra-fine powder grinding mills. This has several benefits, including:

Our Projects

Copyright © ZENITH, All Right Reserved.