Pyrophyllite industrial powder grinding mills play a pivotal role in unlocking the versatile properties of pyrophyllite for multiple industrial applications. These mills offer high efficiency, adjustable particle size distribution, and enhanced product quality. The ceramics, paint, plastics, and agriculture industries benefit from the unique properties of finely ground pyrophyllite powders.

24 Online Service

Pyrophyllite, a fascinating and versatile mineral, has garnered attention for its distinctive properties and various applications in different industries. Derived from the Greek words “pyr” meaning fire and “phyllon” meaning leaf, pyrophyllite boasts a unique leaf-like structure and intriguing characteristics.

Pyrophyllite belongs to the phyllosilicate group of minerals, sharing similarities with talc and mica. Its chemical formula is Al2Si4O10(OH)2, indicating its high aluminum and silicon content. The mineral forms in metamorphic environments, particularly during the alteration of aluminum-rich rocks in the presence of hydrothermal fluids. Over time, heat, pressure, and fluid interactions cause the transformation of these rocks into pyrophyllite.

Pyrophyllite showcases several intriguing physical properties that make it stand out among other minerals. Its color can range from white to various shades of gray, green, or yellow, with a pearly or greasy luster. The mineral’s distinctive leaf-like structure results in its excellent cleavage, allowing it to split into thin sheets or flakes. Its hardness typically ranges from 1 to 2.5 on the Mohs scale, making it relatively soft and easily malleable.

Moreover, pyrophyllite possesses a low specific gravity, ranging from 2.65 to 2.85, and exhibits excellent thermal stability. It can withstand high temperatures without significant alteration or degradation, making it an attractive material for various applications.

Pyrophyllite stone, a remarkable mineral with a rich history, has gained recognition in various industries due to its unique properties and versatility. Known for its fine-grained texture and attractive appearance, pyrophyllite has found applications in areas ranging from art and crafts to industrial manufacturing.

Pyrophyllite is primarily mined from metamorphic rocks formed through the alteration of aluminosilicate minerals under intense heat and pressure. The largest deposits of pyrophyllite can be found in countries such as China, India, the United States, Brazil, and Canada. The mineral is typically extracted through mining operations, followed by processing to obtain the desired size and purity required for different applications.

Pyrophyllite’s remarkable aesthetic qualities make it a popular choice among artists and sculptors. Due to its fine-grained structure and ease of carving, it is often used in the creation of intricate sculptures, figurines, and ornamental objects. The mineral’s color range, which includes white, gray, green, and brown, adds to its appeal and versatility in artistic endeavors.

The industrial applications of pyrophyllite stone are diverse and extensive. Its thermal stability and low thermal expansion coefficient make it an ideal material for refractory products used in the construction of kilns, furnaces, and crucibles. Pyrophyllite’s electrical insulation properties also find application in the manufacturing of high-temperature electrical components.

Additionally, pyrophyllite serves as a crucial ingredient in the production of ceramics, including pottery, porcelain, and bone china. It enhances the plasticity and workability of clay while imparting unique qualities to the finished product, such as increased strength and improved resistance to thermal shock.

Moreover, the mineral’s lubricating and anti-adhesive properties make it a valuable additive in the manufacturing of industrial lubricants, greases, and coatings. Pyrophyllite’s ability to reduce friction and provide thermal stability ensures the smooth operation of machinery and extends their service life.

Pyrophyllite’s remarkable properties have also found applications beyond the realms of art and industry. In agriculture, it is used as a soil amendment due to its ability to improve soil structure, increase water retention, and enhance nutrient availability. Pyrophyllite’s presence helps in promoting healthy root development and overall plant growth.

Furthermore, the mineral has been utilized in the cosmetics industry, particularly in skincare products. It acts as a natural filler, improving the texture and spreadability of creams and lotions, while its absorbent properties make it effective in oil control formulations.

Pyrophyllite, a versatile mineral found abundantly in various regions around the world, holds immense potential due to its unique properties. Its fine-grained nature, low hardness, and excellent thermal stability make it an ideal material for diverse applications, ranging from ceramics and refractories to polymers and paints. However, unlocking the full potential of pyrophyllite requires a carefully crafted grinding process that enhances its properties and enables its utilization in various industries.

Grinding is an essential process in the world of minerals and materials engineering. It involves reducing the size of raw materials to obtain finely ground particles suitable for further processing. The significance of the grinding process lies in its ability to enhance the material’s surface area, reactivity, and performance characteristics. Pyrophyllite, with its inherent properties, can be further refined through grinding, resulting in improved performance and expanded applications.

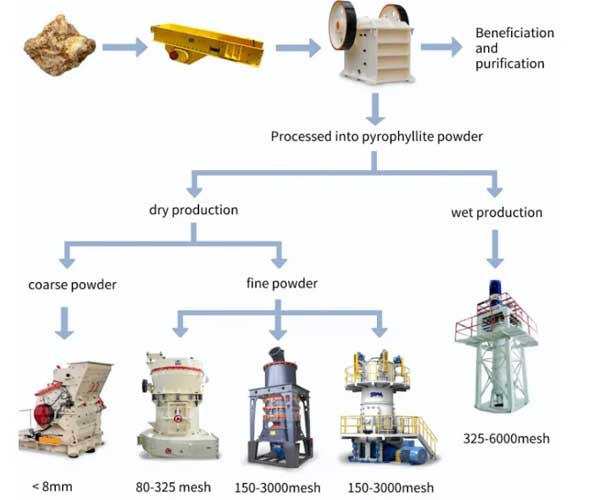

Dry grinding is a widely used method for pyrophyllite processing. It involves the use of mechanical forces, such as impact and attrition, to break down the raw material into smaller particles. In this process, pyrophyllite is typically subjected to high-speed milling, using equipment such as ball mills, hammer mills, or jet mills. The choice of equipment depends on the desired particle size and the specific requirements of the end application.

Wet grinding, as the name suggests, involves the addition of liquid, usually water or a specific grinding solution, to the pyrophyllite during the grinding process. This method offers several advantages, including better control over particle size distribution, reduced dust generation, and improved flowability of the final product. Wet grinding is often preferred when the pyrophyllite needs to be finely ground to achieve specific performance targets.

Grinding significantly increases the surface area of pyrophyllite particles, exposing more active sites for chemical reactions. This enhanced surface area improves the reactivity of pyrophyllite in various applications, such as catalysts and adsorbents, where increased surface area translates into higher efficiency and performance.

Pyrophyllite grinding can lead to improved mechanical properties, such as increased hardness and tensile strength. These enhancements make pyrophyllite an attractive option for reinforcing materials in composites and structural applications, where strength and durability are crucial.

Pyrophyllite already possesses excellent thermal stability, but grinding can further enhance its resistance to high temperatures. This property makes it valuable in industries like refractories, where pyrophyllite can be used as a raw material for heat-resistant bricks, furnace linings, and thermal insulation.

The grinding process opens up new avenues for utilizing pyrophyllite in various industries. Finely ground pyrophyllite can be incorporated into ceramics, polymers, paints, and coatings to improve their performance. It acts as a filler, reinforcing agent, or even as a functional additive, imparting unique properties such as electrical insulation, flame resistance, and thermal conductivity.

In the world of industrial materials, pyrophyllite has emerged as a valuable mineral with a wide range of applications. With its unique properties and abundant availability, pyrophyllite has gained significant attention in various industries. One crucial aspect of harnessing the full potential of pyrophyllite lies in its processing, and the pyrophyllite industrial powder grinding mill stands as a vital tool in this regard.

A pyrophyllite industrial powder grinding mill is a specialized equipment designed to process and grind pyrophyllite into fine powders of varying particle sizes. It utilizes mechanical forces such as compression, impact, and shearing to break down the pyrophyllite particles into smaller fragments. These mills are commonly used in industries like ceramics, paint, rubber, plastics, and agriculture.

Pyrophyllite industrial powder grinding mills are designed with advanced grinding technology, ensuring high efficiency and productivity. The mills utilize energy efficiently, reducing power consumption and optimizing the grinding process.

The grinding mills offer the flexibility to achieve the desired particle size distribution for specific applications. By adjusting the grinding parameters, manufacturers can produce powders with varying fineness levels, catering to diverse industry requirements.

Pyrophyllite industrial powder grinding mills ensure the production of consistent and uniform powders. The mills are equipped with precision control systems that maintain stable grinding conditions, resulting in high-quality products with minimal variations.

Pyrophyllite is widely used in the ceramics industry due to its exceptional thermal stability and low coefficient of expansion. The finely ground pyrophyllite powders obtained from grinding mills serve as essential components in ceramic formulations, improving the strength, stability, and firing characteristics of ceramic products.

Pyrophyllite powders find application in the production of high-quality paints and coatings. The unique plate-like structure of pyrophyllite particles contributes to excellent suspension properties, rheology control, and improved film formation. Grinding mills play a vital role in achieving the desired particle size distribution for optimal paint performance.

Pyrophyllite powders act as reinforcing fillers in the plastics industry, enhancing the mechanical properties of plastic composites. By incorporating finely ground pyrophyllite, manufacturers can improve tensile strength, impact resistance, and dimensional stability of plastic products. Grinding mills ensure the uniform dispersion of pyrophyllite particles within the plastic matrix, maximizing the reinforcement effect.

Pyrophyllite has proven beneficial in agricultural applications. It serves as a carrier for agrochemicals, providing controlled release of nutrients and protecting them from leaching. The finely ground pyrophyllite powders obtained from grinding mills act as excellent soil conditioners, enhancing water retention, soil structure, and nutrient availability.

Pyrophyllite industrial powder grinding mills offer a cost-effective solution for processing pyrophyllite. By efficiently grinding the mineral, these mills minimize material wastage and reduce production costs.

Pyrophyllite grinding mills prioritize environmental sustainability by incorporating energy-efficient designs. Reduced power consumption and optimized grinding processes contribute to lower carbon footprints and decreased environmental impact.

Manufacturers can customize pyrophyllite industrial powder grinding mills to meet specific production requirements. The mills can be tailored to produce powders with desired characteristics, enabling manufacturers to adapt to evolving market demands.

By utilizing pyrophyllite industrial powder grinding mills, manue, these mills have become essential equipment in industries such as ceramics, refractories, plastics, and coatings. As the demand for finely ground pyrophyllite continues to grow, the development of advanced grinding mill technologies will further improve the efficiency and quality of pyrophyllite processing, opening new doors for innovative applications in the future.

Our Projects

Copyright © ZENITH, All Right Reserved.