A sand crusher, also known as a sand making machine, is a machine used to crush rocks and other materials into smaller particles to create sand. Sand crushers are commonly used in construction and manufacturing industries, where sand is needed in large quantities.

24 Online Service

Sand is one of the most essential materials used in the construction industry, which makes it an integral part of modern society. Sand is used in the production of concrete, glass, asphalt, and many other products. The high demand for sand has led to an increase in the need for sand making processes.

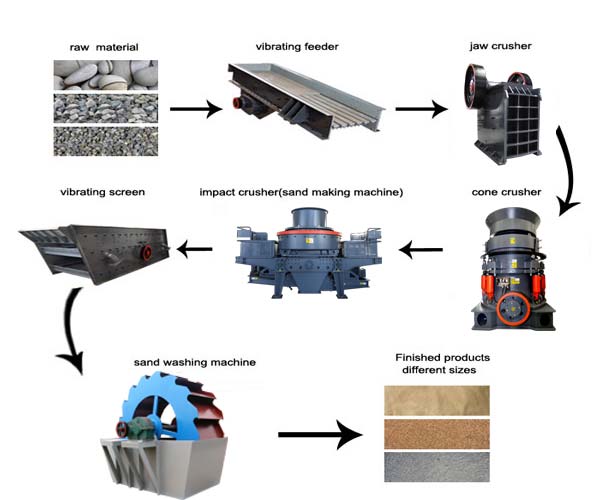

The sand making process is the method of producing sand from rocks and other minerals. The process involves breaking down large rocks into smaller pieces using machines called crushers. After the rocks are crushed, they are transported to a machine called a sand making machine, which produces sand particles of different sizes by using a centrifugal force.

The sand making process involves several stages, including crushing, screening, and washing. These stages are essential in producing high-quality sand that is suitable for use in construction and other industries.

The first stage of the sand making process is crushing. Large rocks are broken down into smaller pieces using crushers. The crushers break down the rocks by applying pressure to them. The pressure causes the rocks to break into smaller pieces, which are then transported to the next stage of the process.

After the rocks are crushed, they are transported to a screening machine. The machine separates the crushed rocks into different sizes. The different sizes are essential because they are used for different purposes. For example, larger particles are used in the production of concrete, while smaller particles are used in the production of asphalt.

The final stage of the sand making process is washing. The washed sand is essential in removing impurities that may affect the quality of the sand. The washing process involves the use of water to remove the impurities. The washed sand is then transported to a drying machine, where it is dried before being packaged and transported to various industries.

The sand making process has several advantages, including:

The sand making process produces high-quality sand that is suitable for use in construction and other industries. The sand is free of impurities, making it ideal for use in various products.

The sand making process produces sand particles of consistent quality. This consistency ensures that the sand is suitable for use in various industries, and it also ensures that the sand meets the required standards.

The sand making process is cost-effective compared to other methods of producing sand. The process involves using machines to crush rocks and other minerals, reducing the cost of labor and transportation.

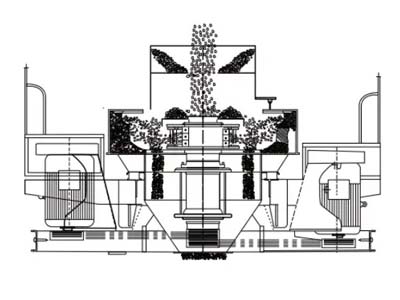

Sand crushers work by breaking down large rocks and other materials into smaller particles. The process begins with the feeding of the material into the machine. The material is then crushed by the rotating blades, which break it down into smaller pieces. The smaller pieces are then fed into a screen, where the sand particles are separated from the larger pieces. The sand particles are then collected and stored, ready for use in construction or manufacturing.

One of the most common machines used for this purpose is a rock crusher. A rock crusher is a machine that uses mechanical force to break down large rocks into smaller pieces. These machines come in different sizes and types, each designed to handle specific types of rock and sand production requirements.

The primary mechanism of a rock crusher is a large metal plate, referred to as a jaw crusher, which is used to crush rocks into smaller sizes. The rock is fed into the jaw crusher and moves towards the opposite side, where it is crushed between the plate and a fixed surface. The resulting pieces are then fed into a secondary crusher, which further breaks down the rock into smaller sizes. The process is repeated until the rock is small enough to be turned into sand.

Another machine commonly used for turning rock into sand is a vertical shaft impactor (VSI). Unlike a rock crusher, a VSI uses a high-speed rotor to accelerate rocks and throw them against a stationary anvil. This impact causes the rocks to break down into smaller pieces and eventually turn into sand. VSI machines are particularly effective at producing sand with a consistent shape and size, making them a popular choice for use in the construction industry.

In addition to rock crushers and VSIs, there are other machines that can turn rock into sand, including cone crushers and gyratory crushers. These machines work in a similar way to rock crushers, but they use a different mechanism to break down the rock into smaller pieces. Cone crushers, for example, use a rotating cone to crush rocks, while gyratory crushers use a spinning head and a concave surface to break down rocks.

Sand making machines are widely used in the construction industry, particularly in the production of concrete, cement, and other building materials. These machines are used to produce high-quality sand that is used as a raw material in various construction applications. Sand making machines have become an essential tool for construction companies and contractors who want to produce high-quality sand for their projects.

Sand making machines are designed to produce sand that is of a consistent size and shape. This is achieved through the use of special rollers that crush and grind the sand particles until they are of the desired size and shape. The resulting sand is then washed and dried before being used in construction applications.

One of the primary applications of sand making machines is in the production of concrete. Concrete is made up of a mixture of cement, sand, and water. The sand used in concrete must be of a consistent size and shape to ensure that the resulting concrete is strong and durable. Sand making machines are used to produce the high-quality sand needed for concrete production.

Sand making machines are also used in the production of asphalt. Asphalt is made up of a mixture of bitumen and aggregates, including sand. The sand used in asphalt production must be of a consistent size and shape to ensure that the resulting asphalt is strong and durable. Sand making machines are used to produce the high-quality sand needed for asphalt production.

Sand making machines are also used in the production of glass. Glass is made up of a mixture of silica, soda ash, and limestone. The sand used in glass production must be of a consistent size and shape to ensure that the resulting glass is clear and strong. Sand making machines are used to produce the high-quality sand needed for glass production.

Sand making machines are also used in the production of ceramics. Ceramics are made up of a mixture of clay, feldspar, and other materials. The sand used in ceramics production must be of a consistent size and shape to ensure that the resulting ceramics are strong and durable. Sand making machines are used to produce the high-quality sand needed for ceramics production.

Sand making machines are also used in the production of foundry sand. Foundry sand is used in the casting process to create molds for metal parts. The sand used in foundry sand must be of a consistent size and shape to ensure that the resulting molds are accurate and precise. Sand making machines are used to produce the high-quality sand needed for foundry sand production.

Our Projects

Copyright © ZENITH, All Right Reserved.