What Is A Grinding Roller Mill

The world of industrial machinery is vast and complex, with various pieces of equipment designed to serve specific purposes. One such piece of equipment that has been gaining traction in recent years is the grinding roller mill. But what is a grinding roller mill, and what makes it so special.

Definition and Functionality

This is achieved through the use of cylindrical rollers, which are mounted on a horizontal axis and rotate at various speeds. These rollers exert pressure on the material being processed, causing it to break down into smaller particles. The final product can be adjusted depending on the gap between the rollers, as well as the speed at which they rotate.

Components of a Grinding Roller Mill

The key components of a grinding roller mill include:

- Rollers: The cylindrical rollers are the heart of the mill, responsible for grinding the material. They are usually made from high-quality, wear-resistant materials such as steel or tungsten carbide, ensuring durability and long-term performance.

- Roller Bearings: These bearings are essential for ensuring smooth and efficient operation, as they allow the rollers to rotate freely while minimizing friction and wear.

- Grinding Table: The grinding table is a flat, circular surface upon which the material is placed for grinding. The rollers press and pulverize the material against this table, achieving the desired particle size.

- Classifier: The classifier is responsible for separating the ground material into different particle sizes, depending on the desired end product. This can be achieved through various methods, such as air classification or sieving.

- Motor and Gearbox: The motor provides the power needed to drive the rollers, while the gearbox is responsible for adjusting the roller speed, which ultimately determines the final particle size.

Many Uses of Roller Mills

Roller mills have long been a staple in various industries, known for their efficiency, precision, and versatility. These mills consist of cylindrical rollers that rotate at adjustable speeds, applying pressure to grind, crush, or pulverize materials into smaller particles. But what exactly are roller mills used for, and which industries can benefit from their application?

Agriculture and Livestock Feed Production

One of the primary uses of roller mills is in the agricultural sector. They are commonly employed to process various grains, such as wheat, barley, corn, and oats, into flour or meal for both human and animal consumption. Roller mills are preferred over other grinding methods, such as hammer mills or stone mills, due to their energy efficiency, precision, and uniform particle size distribution. The resulting feed products are more palatable and easily digestible, promoting the overall health and well-being of livestock.

Roller mills play an important role in the mining and mineral processing industry, where they are utilized to reduce the size of various ores and minerals. This is a crucial step in the extraction process, as it enables the separation of valuable minerals from waste material. Roller mills are particularly well-suited for this task, as they offer precise control over particle size and produce a uniform product, which facilitates the subsequent separation process. Some of the materials commonly processed in roller mills include limestone, coal, and copper, among others.

Cement Manufacturing

In the cement manufacturing process, roller mills are used to grind raw materials such as limestone, clay, and shale into a fine powder called raw meal. This powder is then heated in a kiln to produce clinker, an intermediate product that is subsequently ground into cement. Roller mills are preferred in this industry because they can handle the high abrasiveness of raw materials, provide a consistent and uniform product, and consume less energy compared to other grinding methods like ball mills.

Chemical and Pharmaceutical Industries

The chemical and pharmaceutical industries also rely on roller mills for the processing of various materials. In the chemical industry, roller mills are employed to grind pigments, resins, and inorganic chemicals into fine powders, which can then be used in the formulation of various products. Similarly, in the pharmaceutical industry, roller mills are used to produce powders of consistent particle size for the formulation of medications, ensuring their efficacy and safety. The precision and control offered by roller mills make them an ideal choice for these sensitive applications.

Food and Beverage Industry

Roller mills are widely used in the food and beverage industry for the grinding of grains, spices, and other ingredients. These mills offer a high degree of precision and control over particle size, ensuring that the resulting powders can be easily incorporated into various food items. Examples of products produced using roller mills include flour for baking, cocoa powder for chocolate production, and coffee grounds for brewing. The uniform particle size distribution achieved with roller mills ensures a consistent flavor and texture in the final product.

Advantages of Roller Mills

There are several benefits to using roller mills across various industries, some of which include:

- Energy Efficiency: Roller mills are more energy-efficient than other grinding methods, such as ball mills or hammer mills, due to their reliance on pressure rather than impact force to break down materials.

- Precision and Control: Roller mills offer a high level of control over the final product’s particle size, ensuring consistent and uniform end products that meet industry standards.

- Versatility: The adjustable speed and gap between rollers make roller mills highly versatile, allowing them to be used for a wide range of materials and particle sizes.

Two Types of Grinding Roller Mills

Grinding roller mills have become a crucial component in various industries, thanks to their ability to grind, crush, or pulverize a wide range of materials. These mills primarily consist of cylindrical rollers mounted on a horizontal axis and rotating at varying speeds. Depending on the application, grinding roller mills can be broadly classified into two types: vertical roller mills and horizontal roller mills.

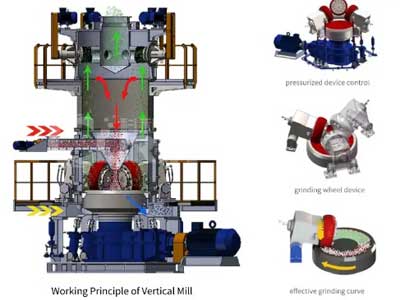

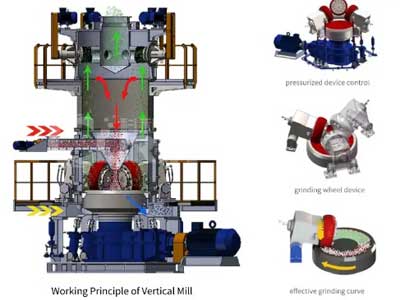

Vertical roller mills, as the name suggests, feature rollers oriented vertically and are particularly well-suited for the grinding of various materials in large-scale industrial settings. This type of mill has gained popularity due to its energy efficiency, low maintenance, and versatility.

- Structure and Functioning: In vertical roller mills, the grinding table is situated horizontally, while the rollers are mounted vertically above it. The material to be ground is fed onto the grinding table, and the rollers exert pressure on it, causing it to be crushed and ground. The ground material then falls through the center of the table and is collected below, while the larger particles are carried by the airflow back onto the table for further grinding.

- Applications: Vertical roller mills are widely used in various industries, including cement production, power generation, and mining. They are particularly well-suited for the grinding of raw materials, clinker, coal, and minerals, such as limestone and copper ore.

- Advantages: Vertical roller mills offer several advantages over other grinding methods, such as energy efficiency, low maintenance, and the ability to process large quantities of material. The vertical orientation of the rollers allows for the efficient use of gravity, reducing the energy consumption and improving the overall efficiency of the grinding process. Furthermore, vertical roller mills are designed to handle a wide range of materials and can be easily adjusted to produce the desired particle size.

- Limitations: One limitation of vertical roller mills is their relatively high initial investment cost. Additionally, these mills may require a more sophisticated infrastructure, such as dust collection systems, to manage the large amounts of fine particles generated during the grinding process.

Horizontal roller mills, on the other hand, feature rollers oriented horizontally and are commonly used in smaller-scale applications, particularly in the food and agricultural sectors.

- Structure and Functioning: In horizontal roller mills, the grinding table and the rollers are both situated horizontally. The material to be ground is fed between the rollers, which rotate at varying speeds, applying pressure on the material and causing it to break down into smaller particles. The particle size can be adjusted by changing the gap between the rollers or by adjusting the roller speed.

- Applications: Horizontal roller mills are widely used in the food and agricultural sectors for the grinding of grains, such as wheat, barley, and corn, into flour or meal. They are also employed in the processing of spices, coffee, and cocoa, among other food products.

- Advantages: Horizontal roller mills offer several advantages, such as a compact design, easy adjustability, and precise control over the particle size. The horizontal orientation of the rollers allows for a more uniform distribution of pressure across the grinding table, resulting in a consistent and uniform end product.

- Limitations: One limitation of horizontal roller mills is their lower throughput capacity compared to vertical roller mills. Additionally, they may be less energy-efficient than vertical roller mills in certain applications, particularly when grinding harder materials.

What is the price of Grinding roller mill machinery in India

Grinding roller mill machinery has become an essential component in various industries, thanks to its ability to grind, crush, or pulverize a wide range of materials. These mills are particularly popular in the agricultural, mining, and cement production sectors, among others. As a result, there is a growing demand for grinding roller mill machinery in India, where the industrial sector continues to expand rapidly.

Factors Influencing the Price of Grinding Roller Mill Machinery in India

The price of grinding roller mill machinery in India is influenced by several factors, including the type of mill, its capacity, material, and manufacturing quality. Some of these factors are outlined below:

- Type of Mill: The price of grinding roller mill machinery largely depends on whether it is a vertical or horizontal roller mill. Vertical roller mills, which are more suitable for large-scale industrial applications, tend to be more expensive than horizontal roller mills, which are typically used in smaller-scale settings.

- Capacity: The grinding capacity of the mill is another critical factor that influences its price. Mills with higher capacities, capable of processing larger quantities of material, are generally more expensive than those with lower capacities.

- Material and Manufacturing Quality: The quality of the materials used in the construction of the mill, as well as the manufacturing process, can have a significant impact on its price. Mills made from high-quality, wear-resistant materials like steel or tungsten carbide, and those manufactured using cutting-edge technologies, are typically more expensive than those made from lower-quality materials or using traditional manufacturing methods.

- Brand and After-Sales Support: The reputation of the manufacturer, as well as the level of after-sales support they provide, can also influence the price of grinding roller mill machinery. Established brands with a proven track record of producing high-quality, reliable machinery, and offering comprehensive after-sales support, may command higher prices than lesser-known or newer brands.

Price Range of Grinding Roller Mill Machinery in India

Given the factors mentioned above, the price of grinding roller mill machinery in India can vary widely. While it is challenging to provide an exact price range without considering the specific requirements of each buyer, the following estimates can serve as a general guideline:

Horizontal Roller Mills: The price of horizontal roller mills in India can range from approximately INR 1 lakh (USD 1,300) for smaller, lower-capacity models to INR 10 lakhs (USD 13,000) for larger, higher-capacity models.

Vertical Roller Mills: The price of vertical roller mills in India can range from approximately INR 10 lakhs (USD 13,000) for smaller, lower-capacity models to INR 1 crore (USD 130,000) or more for larger, higher-capacity models.

It is essential to note that these price ranges are only indicative and can vary depending on the factors discussed earlier.

Cost-Effective Options for Buyers

For buyers looking for cost-effective grinding roller mill machinery in India, there are several options to consider:

- Local Manufacturers: Indian manufacturers have made significant strides in the development and production of grinding roller mill machinery. Opting for locally manufactured mills can be more cost-effective due to lower transportation costs and the potential for better after-sales support.

- Used Machinery: Another option for cost-conscious buyers is to consider purchasing used or refurbished grinding roller mill machinery. These mills can be significantly more affordable than new models, while still offering reliable performance. However, it is crucial to thoroughly inspect the machinery and ensure that it is in good working condition before purchase.

High-Quality Industrial Grinding Roller Mills with Large Capacity

Industrial grinding roller mills have become indispensable components in various sectors, thanks to their ability to grind, crush, or pulverize a wide range of materials with remarkable efficiency and precision. These mills are particularly popular in the mining, cement production, and agricultural sectors, among others. When it comes to high-quality industrial grinding roller mills with large capacity, several factors come into play, such as the type of mill, design, and material quality.

Features of High-Quality Industrial Grinding Roller Mills with Large Capacity

- Robust Design: High-quality grinding roller mills with large capacity are designed to withstand the rigors of continuous operation in demanding industrial environments. This is achieved through the use of robust materials and construction techniques, as well as the incorporation of advanced technologies to optimize grinding efficiency, minimize wear, and extend the mill’s lifespan.

- Superior Material Quality: High-quality grinding roller mills are manufactured using top-tier materials, such as wear-resistant steel or tungsten carbide, to ensure maximum durability and performance. These materials are specifically designed to resist wear, corrosion, and other forms of degradation, resulting in a longer-lasting, more efficient mill.

- Advanced Technologies: Large capacity grinding roller mills often incorporate advanced technologies that enhance grinding efficiency, control particle size distribution, and reduce energy consumption. Some of these technologies include intelligent control systems, dynamic classifiers, and hydraulic or pneumatic pressure systems, which work together to ensure optimal grinding performance.

- Versatility: High-quality industrial grinding roller mills with large capacity are versatile enough to handle a wide range of materials, from soft and friable to hard and abrasive. This versatility is achieved through the use of adjustable roller speeds, gaps, and pressure settings, allowing the mill to be easily adapted to different materials and desired particle sizes.

- Ease of Maintenance: Large capacity grinding roller mills are designed for ease of maintenance, with features such as easily accessible components, quick-release mechanisms, and modular designs that facilitate the replacement of worn parts. These features not only minimize downtime but also reduce maintenance costs over the life of the mill.

Benefits of High-Quality Industrial Grinding Roller Mills with Large Capacity

- Improved Productivity: The large capacity of these grinding roller mills allows for the processing of vast amounts of material in a relatively short period, resulting in improved productivity and higher throughput.

- Enhanced Efficiency: The use of advanced technologies and high-quality materials in the construction of large capacity grinding roller mills ensures optimal grinding efficiency, reducing energy consumption and lowering operating costs.

- Consistent Product Quality: High-quality industrial grinding roller mills with large capacity are designed to provide precise control over particle size distribution, resulting in a uniform, high-quality end product that meets industry standards and customer specifications.

- Reduced Downtime: The robust design and ease of maintenance features found in high-quality grinding roller mills with large capacity help minimize downtime due to maintenance or component failure, ensuring continuous operation and maximizing productivity.

- Industries Benefiting from High-Quality Industrial Grinding Roller Mills with Large Capacity

- Cement Production: Grinding roller mills with large capacity are essential in the cement production process, where they are used to grind raw materials such as limestone, clay, and shale into a fine powder called raw meal. The mills’ efficiency and precision make them ideal for this application, ensuring consistent product quality and reduced energy consumption.

- Mining and Mineral Processing: In the mining and mineral processing industries, grinding roller mills with large capacity are utilized to reduce the size of various ores and minerals, facilitating the extraction of valuable components. The mills’ versatility, efficiency,