Vietnam’s quartz grinding process involves the use of modern techniques and equipment to overcome challenges related to deposit quality, environmental concerns, and technological limitations. By adhering to strict quality control and standards, Vietnam ensures the production of high-quality quartz powder, contributing significantly to the global quartz industry.

24 Online Service

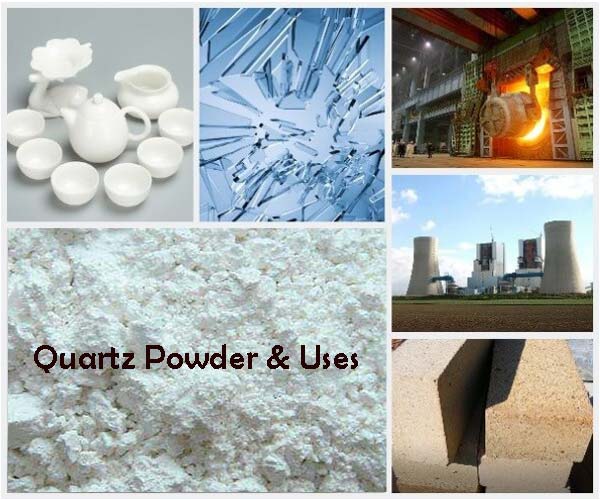

Quartz powder, also known as silica powder, is a crucial industrial material with a wide range of applications in various industries. Composed of silicon dioxide, it is derived from the mineral quartz, one of the most abundant minerals on Earth. Quartz powder’s exceptional properties make it indispensable in sectors such as glass manufacturing, ceramics, electronics, and construction.

Quartz powder is a finely ground form of silica, characterized by its purity and consistent particle size distribution. It is produced by crushing and grinding high-quality quartz crystals or silica-rich ores into a fine powder. The powder’s appearance varies from white to off-white and is odorless, non-toxic, and chemically inert. These properties make quartz powder a preferred choice for a multitude of industrial applications.

One of the primary applications of quartz powder is in the glass industry. It acts as a key raw material in the production of various types of glasses, including flat glass, container glass, fiberglass, and specialty glasses. Quartz powder imparts transparency, high melting point, and thermal shock resistance to glass products, making them suitable for architectural purposes, automotive windshields, and solar panels.

Quartz powder plays a significant role in the ceramics industry due to its high silica content and low coefficient of thermal expansion. These properties enhance the strength, durability, and thermal stability of ceramic products. It is used in the production of sanitary ware, tiles, porcelain, and refractory materials.

The electronics industry relies heavily on quartz powder for manufacturing semiconductor devices and electronic components. Quartz powder is utilized in the production of quartz crystal oscillators, which are essential in maintaining precise frequency and timing in various electronic devices, such as watches, clocks, computers, and communication equipment.

In the construction sector, quartz powder is employed as a filler and extender in various building materials, including paints, coatings, adhesives, and concrete. Its high hardness and resistance to chemical weathering contribute to the durability and longevity of construction materials.

Vietnam, a country located in Southeast Asia, is known for its abundant natural resources. Among these resources lies a considerable deposit of quartz. The northern and central regions of Vietnam host vast reserves of high-quality quartz, making the country a promising potential source for quartz powder production.

Vietnam’s significant reserves of quartz indicate a reliable and sustainable source of raw material for quartz powder production. These reserves can support the growing demand from various industries, both domestically and internationally.

Exploiting its quartz resources for powder production could positively impact Vietnam’s economy. The production and export of quartz powder would create employment opportunities, foster industrial growth, and contribute to the country’s foreign exchange earnings.

Vietnam has been striving to diversify its industrial base to reduce dependency on traditional sectors. By developing quartz powder production capabilities, the country can tap into new industrial opportunities and foster technological advancements.

With the global demand for quartz powder on the rise, Vietnam can position itself as a reliable exporter in the international market. The country’s strategic location in Southeast Asia could further facilitate access to markets in neighboring regions.

As environmental concerns escalate, Vietnam’s potential involvement in quartz powder production can prioritize sustainable practices. By adhering to responsible mining and production methods, the country can ensure minimal environmental impact and comply with international regulations.

One of the critical processes involved in extracting the full potential of quartz is grinding. Grinding mills play a crucial role in processing quartz to obtain fine powder, which is further utilized in numerous applications, such as glassmaking, ceramics, electronics, and construction materials.

Quartz grinding mills are mechanical devices designed to break down quartz into finer particles. The primary principle of operation involves applying mechanical force to the quartz material, causing it to fracture and reduce in size. The grinding process ensures that the quartz particles attain the desired size and shape for their intended application.

Ball mills are commonly used for grinding and milling materials in the mining and construction industries. In a ball mill, the quartz is placed inside a rotating cylinder, partially filled with steel balls of varying sizes. As the cylinder rotates, the steel balls collide with the quartz, breaking it down into smaller particles.

Raymond mills, also known as roller mills, are equipped with multiple rollers that revolve around a central axis. The quartz is fed between the rollers and ground under pressure and shear forces.

These mills consist of a rotating table with rollers. Quartz is fed into the table, and the rollers crush and grind the material.

Jet mills use high-speed air jets to impact the quartz particles, reducing them to the desired size.

Vietnam is known for its vast deposits of high-quality quartz, making it a significant player in the global quartz industry. The grinding process in Vietnam follows a similar approach to other countries, but it may involve some unique techniques and equipment specific to the region.

The first step in the grinding process is the extraction of quartz from mines. In Vietnam, quartz deposits are carefully selected to ensure high purity and quality. Advanced mining techniques are employed to minimize impurities and maintain the desired quartz grade.

The extracted quartz is then crushed into smaller fragments using primary crushers. This initial crushing prepares the raw material for further grinding.

After the initial crushing, the quartz fragments are fed into grinding mills. In Vietnam, a combination of ball mills and Raymond mills is commonly used for grinding. The selection of the mill type depends on factors such as the required particle size, capacity, and efficiency.

Once the quartz is ground into a fine powder, it goes through a classification process to separate particles of different sizes. This ensures that the final product meets the specified particle size distribution.

In some cases, the ground quartz powder is dried to reduce moisture content, enhancing the powder’s flowability and handling properties.

Despite the abundance of quartz deposits in Vietnam, there are certain challenges faced during the grinding process:

The quality of quartz deposits can vary, affecting the efficiency of the grinding process and the final product’s quality. To address this, careful selection of mining sites and advanced ore sorting technologies are employed to ensure the highest grade of quartz is used for grinding.

Quartz grinding generates fine particles and dust, which can lead to environmental issues if not managed properly. Enclosed grinding systems, dust collectors, and effective ventilation are employed to mitigate the impact on the environment.

Outdated or inefficient grinding equipment may result in lower productivity and higher energy consumption. Upgrading to modern, energy-efficient grinding mills can address these limitations and improve overall efficiency.

To overcome the challenges faced during the quartz grinding process in Vietnam, the following solutions and improvements can be considered:

Continuous research and development efforts can lead to the discovery of better grinding techniques and equipment, further enhancing the efficiency and quality of the process.

Implementing sustainable practices in the mining and grinding processes can reduce the environmental footprint. Recycling and reusing water, implementing cleaner energy sources, and responsible waste disposal are some steps that can be taken.

The Vietnamese government can enforce strict regulations and standards for the quartz grinding industry to ensure environmental protection and adherence to quality norms.

Maintaining high-quality standards during the grinding process is crucial to produce consistent and reliable quartz powder. In Vietnam, quality control measures involve stringent testing and analysis of the ground quartz powder to ensure it meets the desired specifications.

Particle size distribution is closely monitored to ensure that the powder meets the required specifications for different applications.

The quartz powder undergoes rigorous testing to check for impurities and ensure high purity levels.

The ground quartz powder is tested for performance characteristics in specific applications, such as glassmaking or ceramics, to guarantee its suitability.

Our Projects

Copyright © ZENITH, All Right Reserved.