Gold mining plants are intricate operations that rely on an array of specialized equipment to extract the precious metal efficiently. From the initial stages of excavation to the final product, each step demands purpose-built machinery.

24 Online Service

The process of open-pit mining, a prevalent method for gold extraction, causes deforestation, disrupts biodiversity, and alters landscapes irreversibly. The excavation of vast areas for mining operations destroys natural habitats, displacing wildlife and jeopardizing the delicate balance of ecosystems.

Recognizing the urgent need for change, there is a growing global movement towards sustainable and responsible mining practices. Stakeholders, including governments, mining companies, and environmental organizations, are advocating for the adoption of eco-friendly technologies, improved waste management, and stringent regulations to minimize the environmental impact of mining operations.

One promising avenue for sustainable mining is the utilization of cleaner and more efficient extraction methods. Innovations such as green chemistry and bioleaching offer alternatives to the environmentally harmful chemicals traditionally used in gold extraction. These methods reduce the ecological footprint of mining activities and mitigate the long-term damage inflicted on ecosystems.

Additionally, embracing circular economy principles in mining can contribute to minimizing waste and maximizing resource efficiency. Recycling and reusing materials from mining processes, as well as incorporating renewable energy sources, are crucial steps towards creating a more sustainable and responsible mining industry.

These heavy-duty machines are the workhorses of gold mining, used for stripping away overburden and exposing the gold-bearing ore.

Modern gold mining relies on advanced drilling equipment to reach deposits situated deep within the Earth. Drill rigs equipped with cutting-edge technology enable precise extraction.

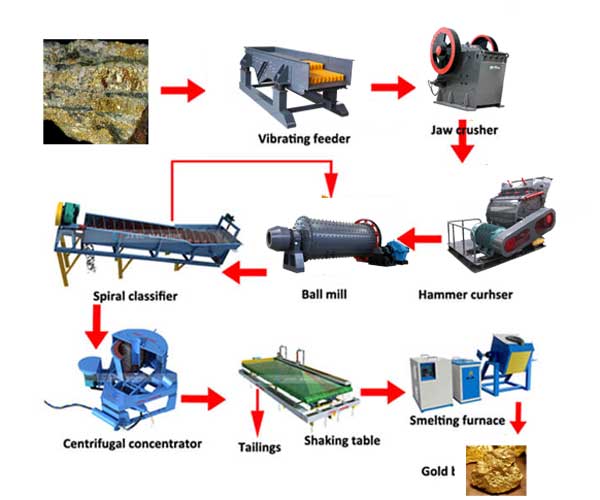

The extracted ore is often composed of large chunks that need to be reduced in size for further processing. Crushers and grinding mills break down the ore into manageable particles.

Gravity plays a crucial role in gold extraction. Equipment like jigs, shaking tables, and centrifugal concentrators exploit the differences in density between gold and other minerals, allowing for effective separation.

Flotation is another key process that helps separate gold from other minerals. Froth flotation equipment uses the buoyancy of gold particles to isolate them from the ore.

In the case of low-grade ore, cyanide leaching is employed to dissolve the gold. Specialized tanks facilitate this chemical process, freeing the gold for further refinement.

After extraction, the gold undergoes refining processes to achieve the desired purity. Smelting furnaces, electrolytic cells, and other refining equipment play a crucial role in this final stage.

Understanding the machinery is incomplete without insight into the intricate processes that define gold extraction:

Geologists employ a combination of remote sensing, geological mapping, and drilling to locate gold deposits.

Excavators and bulldozers remove overburden to expose the ore. Advanced drilling techniques ensure precise extraction without damage to the deposit.

Crushing and grinding reduce the ore size, facilitating subsequent processes. Gravity separation and flotation isolate gold particles, while cyanide leaching extracts gold from low-grade ore.

The final step involves refining the gold to achieve the desired purity. Various methods, including smelting and electrolysis, are employed to remove impurities.

One of the key areas of innovation in gold mining equipment lies in the design phase. Manufacturers are increasingly prioritizing sustainability by incorporating smart design principles. This includes the use of modular components, which not only simplifies maintenance but also allows for easier upgrades and replacements, extending the lifespan of the equipment.

In the pursuit of sustainability, the materials used in mining equipment have undergone a significant transformation. Traditional mining equipment often relied on resource-intensive materials with high environmental costs. However, modern equipment incorporates advanced materials such as high-strength alloys and composites, reducing weight without compromising durability.

Energy consumption is a major concern in mining operations. Innovations in gold mining equipment have led to the integration of energy-efficient technologies that not only reduce operational costs but also minimize the industry’s carbon footprint.

Gold mining has historically been associated with water pollution and excessive water usage. Sustainable gold mining equipment addresses these issues through innovative water management and conservation technologies. Closed-loop water systems minimize the release of contaminated water into surrounding ecosystems, while advanced filtration systems ensure that water used in mining processes is efficiently treated and recycled. These measures not only protect local water sources but also contribute to the overall sustainability of the mining operation.

Our Projects

Copyright © ZENITH, All Right Reserved.