A mobile crusher is a versatile, self-contained, and transportable heavy-duty machine designed for crushing rocks, ores, and construction waste materials. It allows for on-site processing and recycling, reducing the need to transport materials to and from crushing facilities.

24 Online Service

The construction industry has witnessed significant technological advancements in recent years, with mobile crushers playing a crucial role in improving efficiency, reducing costs, and promoting sustainable practices.

With its mobility and flexibility, a mobile crusher can quickly adapt to various job sites and project requirements, making it an indispensable tool in the modern construction industry.

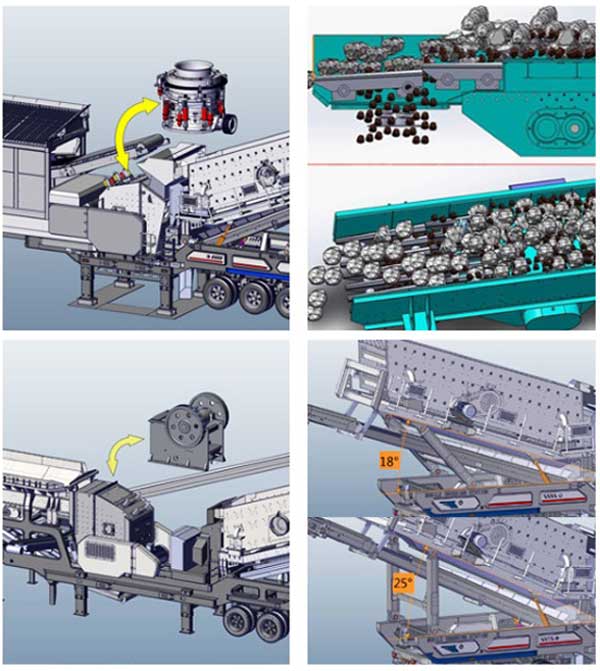

A typical mobile crusher consists of several primary components:

Mobile crushers are available in different types, each with its own set of features and advantages:

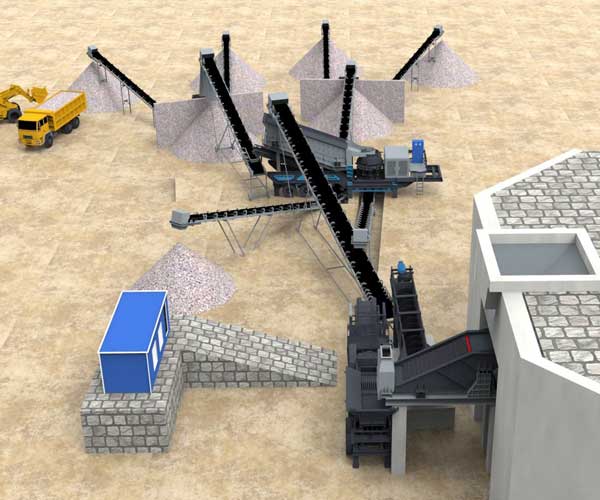

The mobile crushing process has transformed the construction and mining industries by offering an efficient and environmentally friendly solution for on-site material processing. This innovation has led to reduced transportation costs, improved productivity, and sustainable practices.

The mobile crushing process involves using a mobile crusher, a self-contained, transportable machine designed to crush rocks, ores, and construction waste materials. The process is carried out on-site, reducing the need to transport materials to and from crushing facilities. The mobile crushing process comprises several stages, including feeding, crushing, screening, and conveying. Here’s a step-by-step guide to how the process works:

The first stage in the mobile crushing process is feeding the raw materials into the crusher. A hopper or vibrating feeder is used to feed the materials, ensuring a continuous and controlled flow. The feeder can be adjusted to maintain the desired feed rate, preventing overloading or underfeeding of the crusher. In some cases, pre-screening may be necessary to remove unwanted materials, such as soil or fine particles, before feeding the material into the crusher.

Once the materials are fed into the crusher, the actual crushing process begins. Depending on the type of mobile crusher, different crushing mechanisms are employed:

Jaw crushers: These crushers use compression force to break down large rocks and materials. They are suitable for processing hard, abrasive materials and are commonly used in quarries and mining operations.

Impact crushers: These crushers use impact force to break down materials, making them suitable for processing softer rocks and materials with low to medium abrasiveness. Impact crushers are often used in recycling applications and for producing high-quality aggregates.

Cone crushers: Cone crushers employ a combination of compression and shearing forces to crush materials. They are widely used in secondary and tertiary crushing applications, particularly for processing hard, abrasive materials.

The crusher’s settings, such as the gap size and crushing force, can be adjusted to achieve the desired output size and shape.

After the materials have been crushed, they are typically passed through a screening system. This stage involves using vibrating screens or other screening equipment to separate the crushed materials into different size fractions. The screens can be adjusted to produce the desired size and shape of the final product. In some cases, multiple screening stages may be required to achieve the desired product specifications.

Once the materials have been crushed and screened, they are transported to a designated location or other processing equipment using conveyor belts. The conveyor system may include multiple belts, transfer points, and discharge points, depending on the project requirements. Conveyor belts are essential in maintaining a continuous flow of materials throughout the mobile crushing process, ensuring efficient and productive operations.

Throughout the mobile crushing process, a central control system is used to monitor and adjust various aspects of the operation. This system allows operators to track the crusher’s performance, make necessary adjustments, and troubleshoot any issues that may arise. By closely monitoring the process, operators can optimize productivity, minimize downtime, and maintain consistent output quality.

Once the mobile crushing process is complete, the final product can be transported to its intended destination for disposal, reuse, or further processing. The crushed materials can be used as aggregates in construction projects, backfill materials, or base layers for roads and infrastructure. In recycling applications, the processed materials can replace new materials, reducing the demand for resources and promoting sustainable practices.

Mobile crushers are a type of machine that allows users to crush large rocks and stones into smaller pieces. They are widely used in mining, construction, and recycling industries, among others. Buying a mobile crusher can be a daunting task, especially if you have never done it before. With so many options available, it can be challenging to know which one to choose. In this article, we will provide a guide on how to buy a mobile crusher.

The first step to buying a mobile crusher is to identify your needs. What type of material do you want to crush? How much material do you need to crush per hour? What is your budget? These are some of the questions you need to ask yourself before you start looking for a mobile crusher. Knowing your needs will help you narrow down your search and make the buying process much easier.

Once you have identified your needs, the next step is to research the market. There are many different types of mobile crushers available, each with its own set of features and benefits. You need to research the different options available and compare them based on your needs and budget.

When buying a mobile crusher, it is important to look for a reputable supplier. A reputable supplier will offer high-quality products, excellent customer service, and after-sales support. Look for reviews and testimonials from other customers to ensure that the supplier is reliable and trustworthy.

Mobile crushers come in different sizes and weights. It is important to consider the size and weight of the machine before making a purchase. If you have limited space, you may need to look for a smaller machine that can easily be moved around. If you need to crush large quantities of material, you may need a larger machine that can handle the load.

The crushing capacity of the mobile crusher is another important factor to consider. The crushing capacity refers to the amount of material that the machine can crush per hour. If you need to crush large quantities of material, you will need a machine with a high crushing capacity. However, if you only need to crush small quantities of material, a machine with a lower crushing capacity may be sufficient.

Mobile crushers are designed to be mobile, but some are more mobile than others. If you need to move the machine around frequently, you will need a machine that is easy to move and transport. Look for machines with wheels or tracks that can easily be moved around.

When buying a mobile crusher, safety should be a top priority. Look for machines with safety features such as emergency stop buttons, safety guards, and warning signs. Make sure that the machine is properly maintained and serviced to ensure that it is always in good working condition.

A warranty is an important factor to consider when buying a mobile crusher. A warranty will protect you against any defects or malfunctions that may occur with the machine. Look for a supplier that offers a warranty on their products, and make sure you understand the terms and conditions of the warranty before making a purchase.

The mobile crusher industry has been growing rapidly in recent years, with China emerging as a major player in the global market. As the world’s largest manufacturer and consumer of mobile crushers, China has an extensive network of manufacturers, suppliers, and distributors that cater to both domestic and international markets.

Mobile crushers are an essential tool for the construction and mining industries. They are used to crush stones, rocks, and other materials into smaller sizes, which can be used for various purposes such as road construction, building construction, and infrastructure development. China is the world’s largest producer of mobile crushers, with a market share of over 50%. The country’s mobile crusher industry has been growing rapidly over the past few years, driven by a growing demand for construction materials and infrastructure development.

China’s mobile crusher market is highly competitive, with several key players dominating the industry.

Shanghai Zenith Machinery Co., Ltd. – This is one of the Main manufacturers of mobile crushers in China. The company produces a wide range of mobile crushers, including jaw crushers, impact crushers, cone crushers, and mobile screens.

Our Projects

Copyright © ZENITH, All Right Reserved.