An impact crusher is a piece of heavy-duty equipment that is designed to crush or break down a variety of materials, including concrete, asphalt, and rock. It is commonly used in quarrying, mining, and recycling industries, where it plays a vital role in producing high-quality aggregates and other materials.

24 Online Service

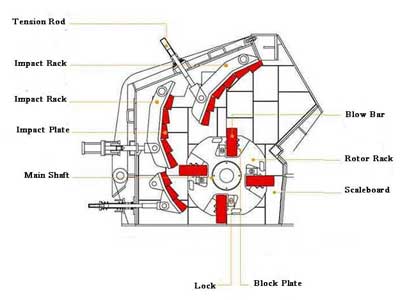

The basic design of an impact crusher consists of a rotor, which rotates at high speeds, and a stationary or semi-mobile frame. The material to be crushed is fed into the rotor, which then impacts the material against the stationary or moving aprons. This impact causes the material to break down and become smaller in size, resulting in the creation of smaller particles that can be used in a variety of applications.

Impact crushers are available in different designs and configurations, each suited to specific applications and material types. The most common types of impact crushers are horizontal shaft impact (HSI) crushers and vertical shaft impact (VSI) crushers.

HSI crushers are designed for primary, secondary, or tertiary crushing of a variety of materials, including concrete, asphalt, and natural stone. They are ideal for crushing large pieces of material and producing a uniform shape. HSI crushers are typically used in aggregate production, mining, and recycling applications.

VSI crushers are designed for tertiary and quaternary crushing of a variety of materials, including hard rock, ore, and slag. They are designed to produce a more cubical-shaped product, making them ideal for use in the production of high-quality aggregates. VSI crushers are typically used in mining, quarrying, and recycling applications.

One of the key benefits of an impact crusher is its ability to produce a high-quality, uniform particle shape. This is achieved through the use of special wear-resistant materials and precision machining techniques, which ensure that the impact crusher is able to deliver consistent performance over a long period of time.

Another benefit of impact crushers is their high capacity and production rate. Due to their high rotor speeds and large feed openings, impact crushers are able to handle a wide range of materials and produce large volumes of output in a relatively short period of time.

In addition, impact crushers are generally more cost-effective than other types of crushers, such as jaw crushers or cone crushers. This is due to their lower capital costs and reduced maintenance requirements, which can result in significant savings over the life of the equipment.

However, there are also some drawbacks to using impact crushers. For example, they can be noisy and generate a lot of dust and debris, which can pose health and safety risks for workers. In addition, they may not be suitable for all materials, particularly those that are abrasive or hard.

An impact crusher is a type of crushing machine that utilizes the principle of impact to reduce the size of materials. It is widely used in construction, mining, and other industries to crush various types of raw materials such as rocks, ore, and concrete.

An impact crusher works by picking up the material from a hopper or storage area and feeding it into the crushing chamber where the rotor rotates at high speed. The material is then struck by the hammer bars, which are fixed on the rotor, and thrown against the impact plates that line the crushing chamber. This impact breaks the material into smaller pieces that can be discharged through the bottom of the crusher.

The crushing action of an impact crusher is caused by a sudden collision between two objects. In this case, the objects are the material being crushed and the hammer bars that are rotating at high speed. The force of this collision causes the material to break into smaller pieces. The size of the pieces depends on the speed of the rotor, the size of the hammer bars, and the distance between the impact plates.

An impact crusher is a type of crushing machine that is used to crush a variety of materials. It works by feeding material into a rotating rotor with a hammer that strikes the material, causing it to be broken down into smaller pieces. The smaller pieces are then discharged through a grate at the bottom of the crusher. Impact crushers have numerous applications in various industries, and their versatility makes them an important tool for many businesses.

One of the primary applications of an impact crusher is in the aggregate and construction industries. In these industries, the crusher is used to break down larger rocks and other materials into smaller pieces that can be used as gravel or in construction projects. This is particularly useful in the creation of concrete, as smaller pieces of stone can be mixed with cement and other materials to create a stronger and more durable finished product.

Another application of impact crushers is in the mining industry. In mining, crushers are used to break down ore deposits into smaller pieces that can be processed further. This is particularly important in the extraction of minerals like gold and silver, which can be found in large deposits but are often mixed with other materials that must be separated before the metal can be extracted.

Impact crushers are also used in the recycling industry. In this industry, the crusher is used to break down large pieces of waste material, such as old cars or appliances, into smaller pieces that can be recycled. This is particularly important in the creation of recycled steel, where old cars and other metal objects are broken down and the metal is extracted for use in new products.

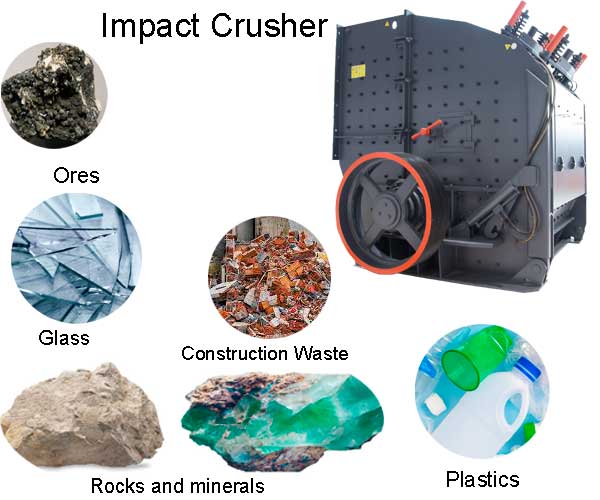

Impact crushers are powerful machines that are designed to crush various types of materials, ranging from soft to hard and brittle materials. These machines use impact force to break down the material, which can be in the form of rocks, ores, minerals, and even construction waste.

One of the primary uses of impact crushers is to crush rocks and minerals. Rocks come in a variety of types, such as igneous, sedimentary, and metamorphic rocks. Depending on the type of rock, it can be soft or hard, and brittle or ductile. Some common types of rocks that can be crushed by impact crushers include limestone, granite, basalt, and sandstone. These rocks are used in construction, landscaping, and other industries.

Minerals are also commonly crushed by impact crushers. Minerals are naturally occurring substances that are solid, inorganic, and have a crystalline structure. Some common minerals that can be crushed by impact crushers include quartz, feldspar, mica, and talc. These minerals are used in a variety of applications, including building materials, electronics, and cosmetics.

Ores are naturally occurring materials that contain a metal or a valuable mineral that can be extracted. Ores are mined from the earth and then processed to extract the metal or mineral. Some common types of ores that can be crushed by impact crushers include copper, gold, iron, and silver. These ores are crushed to a fine powder, which is then processed to extract the metal or mineral.

Impact crushers can also be used to crush construction waste, which includes materials such as concrete, bricks, and asphalt. These materials are typically generated during construction and demolition activities. Crushing construction waste can reduce the amount of waste that ends up in landfills, and can also provide a source of recycled material for new construction projects.

Glass is a material that can be crushed by impact crushers. Glass is made from a mixture of sand, soda ash, limestone, and other minerals. It is a versatile material that can be used in a variety of applications, including windows, mirrors, and containers. However, when glass is no longer needed, it can be recycled by crushing it into small pieces, which can then be used to make new glass products.

Impact crushers can also be used to crush plastic materials. Plastics are synthetic materials that are made from a variety of organic polymers. Plastics are used in a variety of applications, including packaging, electronics, and automotive parts. However, when plastic products are no longer needed, they can be recycled by crushing them into small pieces, which can then be used to make new plastic products.

In the construction industry, one of the most crucial aspects is the use of high-quality materials. Stone materials are commonly used in construction, and crushing these materials can be a time-consuming and expensive process. However, with the use of impact crushers, this process can be made easier and more cost-effective.

Impact crushers are machines that use impact force to crush materials. They work by throwing the materials against a hard surface or a stationary object, causing them to break into smaller pieces. This type of crusher is commonly used in the mining and construction industries to crush large rocks and stones into smaller pieces for use in construction projects.

The use of impact crushers for crushing stone materials has several advantages over other crushing methods. One of the main advantages is that they can crush materials quickly and efficiently. This is because they use the principle of impact force to break the materials, which is more efficient than other methods such as crushing with compression force.

Another advantage of using impact crushers is that they are versatile and can be used for a variety of materials. They can crush materials of different sizes and hardness levels, making them ideal for use in various construction projects. This versatility means that the investment in an impact crusher can be used for a range of applications, making it a more cost-effective option.

In addition to being more efficient and versatile, impact crushers can also save on investment costs. This is because they are designed to be durable and long-lasting, meaning they require minimal maintenance and repair costs. Unlike other types of crushers that require regular maintenance, impact crushers can go for extended periods without needing any significant repairs, which can save companies a lot of money over time.

Another way that impact crushers can save on investment costs is by reducing the need for manual labor. Crushing stones and rocks manually can be a time-consuming and labor-intensive process, which can lead to higher labor costs. However, with the use of impact crushers, the crushing process can be automated, reducing the need for manual labor and saving on labor costs.

Furthermore, impact crushers can also save on transportation costs. This is because they can be placed directly at the construction site, reducing the need to transport the materials to another location for crushing. This can save on transportation costs, which can be a significant expense for construction companies.

Our Projects

Copyright © ZENITH, All Right Reserved.