The calcium carbonate powder machine is an indispensable tool in various industries, enabling the transformation of raw CaCO3 into a fine powder form suitable for numerous applications.The complex interplay of impact, attrition, and compression techniques, combined with the proper control of factors like speed, pressure, and feed rate, ensures the production of high-quality calcium carbonate powder.

24 Online Service

Calcium carbonate, a naturally occurring compound with the chemical formula CaCO3, is one of the most abundant minerals on Earth. It is found in various forms and serves numerous purposes across different industries.

The chemical formula of calcium carbonate, CaCO3, indicates that it is composed of one calcium (Ca) atom, one carbon (C) atom, and three oxygen (O) atoms. Calcium carbonate occurs naturally in various forms and can be found in limestone, marble, chalk, and even seashells. These sources have played a crucial role in shaping the geological history of our planet.

Limestone is a sedimentary rock primarily composed of calcium carbonate. It forms from the accumulation of shells, coral, algal remnants, and other marine organisms over millions of years. The vast limestone deposits around the world have significant economic importance, serving as a primary building material and a raw material for several industrial processes.

Marble is a metamorphic rock that forms when limestone undergoes intense heat and pressure within the Earth’s crust. The recrystallization of calcium carbonate in limestone results in the formation of the distinctive patterns and colors seen in marble. Highly valued for its aesthetic appeal, marble is commonly used in sculpture, architecture, and interior design.

Chalk is a soft, porous form of calcium carbonate primarily composed of the remains of single-celled algae known as coccolithophores. These microscopic organisms lived in ancient oceans and left behind their calcareous shells, which, over time, formed chalk deposits. Chalk is commonly used for writing and drawing, and in the past, it was a popular medium for blackboards.

In various applications, calcium carbonate must be ground to a specific size to achieve desired properties and functionalities. The particle size of calcium carbonate can significantly impact its performance in different industries. Grinding is necessary for the following reasons:

In industries like agriculture and pharmaceuticals, smaller particle sizes of calcium carbonate increase the surface area available for reactions. This results in improved reactivity and more efficient utilization of the compound.

In the plastics, paints, and coatings industries, finely ground calcium carbonate enhances the mechanical properties of the final products. It strengthens the materials and provides better abrasion resistance.

In paper production and the paint industry, finer particles of calcium carbonate contribute to smoother finishes and improved printability.

The performance and effectiveness of calcium carbonate with varying particle sizes depend on the application and industry:

In the construction industry, coarser calcium carbonate particles are typically preferred for cement production, as they contribute to the strength and durability of the final product.

In antacid formulations, finer calcium carbonate particles offer quicker relief due to their increased reactivity in the stomach acid.

The particle size of calcium carbonate significantly affects paper properties. Fine particles improve paper smoothness, while coarser particles enhance opacity.

In the plastics industry, smaller calcium carbonate particles offer better reinforcement and mechanical properties.

Finer calcium carbonate particles in paints and coatings provide smoother finishes and better covering power.

Calcium carbonate, or CaCO3, is a ubiquitous mineral that is essential for a wide range of industrial applications. From construction and agriculture to healthcare and plastics, this versatile compound plays a crucial role in our daily lives. However, to fully harness its potential, it needs to be processed into fine powder form through a complex grinding process.

The calcium carbonate powder machine is a sophisticated piece of equipment designed specifically to grind CaCO3 into fine particles. This machine is a fundamental part of various industries that rely on calcium carbonate in powdered form, such as paints, coatings, plastics, and paper. The powder machine is an indispensable tool in processing raw materials and ensuring their quality meets the stringent requirements of modern applications.

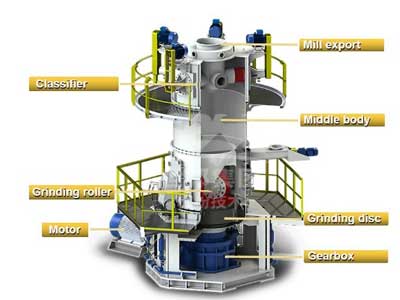

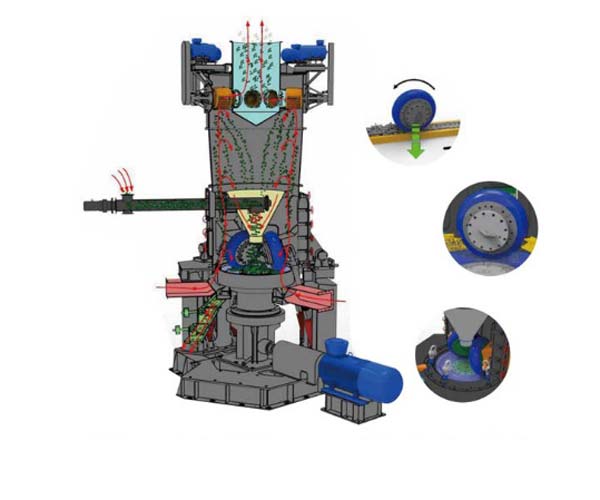

The calcium carbonate powder machine is a complex assembly of several key components, each playing a crucial role in the grinding process. Let’s explore the main components and their functions:

The heart of the calcium carbonate powder machine is the grinding mill. It comes in various forms, such as ball mills, Raymond mills, roller mills, and hammer mills. The grinding mill’s primary function is to break down the bulk CaCO3 into smaller particles, preparing it for further industrial use.

The feeder is responsible for the uniform and controlled feeding of calcium carbonate into the grinding mill. It ensures a steady flow of material, preventing uneven grinding and potential damage to the machine.

After the grinding process, the classifier separates the fine particles from the coarse ones. This classification is vital in ensuring that the final powder has the desired particle size distribution.

During the grinding process, some fine particles may become airborne, posing a health hazard and potentially damaging the surrounding equipment. The dust collector efficiently captures these particles, improving air quality and protecting the overall system.

The grinding process used to break down calcium carbonate into smaller particles involves several techniques, each suited for different applications and desired particle sizes. The primary techniques used are impact, attrition, and compression.

In the impact grinding technique, the material is subjected to high-speed collisions with grinding media or machine components. This causes the calcium carbonate particles to break apart into smaller fragments. Impact mills are effective in producing fine particles and are commonly used in the pharmaceutical and food industries.

Attrition grinding involves the interaction of the material with grinding media, such as balls or pebbles, causing the CaCO3 particles to wear down through friction. This technique is particularly effective for producing ultra-fine particles with a narrow size distribution.

Compression grinding involves applying pressure to the material between two surfaces, resulting in the reduction of particle size. Roller mills and compression crushers are examples of equipment that utilize this technique to produce a wide range of particle sizes.

To achieve the desired particle size and quality of the calcium carbonate powder, controlling various factors during the grinding process is essential.

The rotational speed of the grinding mill directly impacts the grinding efficiency and the final particle size. Higher speeds generally lead to finer particles but can also increase wear on the machine.

In compression grinding, the applied pressure significantly affects the particle size reduction. Optimizing the pressure helps in achieving the desired particle size distribution.

The rate at which calcium carbonate is fed into the grinding mill influences the overall throughput and the size of the final product. Controlling the feed rate ensures steady and efficient grinding.

Calcium carbonate is a versatile mineral used in various industries, and its powder form is widely employed in applications such as plastics, rubber, paper, paint, pharmaceuticals, and agriculture. To produce fine calcium carbonate powder, grinding machines are used.

The ball mill is a widely used machine for grinding calcium carbonate into fine powder. It is composed of a rotating cylindrical shell, partially filled with grinding media such as steel or ceramic balls. The rotation of the shell causes the grinding media to impact and grind the calcium carbonate particles. Ball mills are efficient and versatile, suitable for both wet and dry grinding. They are often used for large-scale production due to their high capacity and ease of operation.

Also known as a pendulum roller mill, the Raymond mill operates by passing the material between two plates, one of which is stationary while the other rotates. The grinding rollers crush the calcium carbonate particles against the stationary plate. This type of mill is well-suited for processing medium-hard materials and provides precise control over particle size distribution.

VRMs are widely used in the cement industry but have found applications in calcium carbonate grinding as well. The material is crushed between rotating grinding rollers and a stationary table. VRMs offer higher energy efficiency compared to ball mills and Raymond mills, making them suitable for fine and ultrafine grinding.

As the name suggests, ultrafine mills are used to produce ultrafine calcium carbonate powder. They utilize centrifugal force to disperse and grind the particles. Ultrafine mills are capable of producing particle sizes in the nanometer range and are crucial in applications that require extremely fine powders, such as in the pharmaceutical industry.

The various particle sizes of calcium carbonate powder find applications across diverse industries:

Coarse calcium carbonate powder is used in agriculture as a soil conditioner to neutralize acidic soils. It also finds applications in construction as a filler material and in the manufacturing of cement and asphalt.

Calcium carbonate powder with medium particle sizes is commonly used in the paper industry as a filler and coating material. It improves the paper’s brightness, opacity, and printability.

Fine calcium carbonate powder is utilized in the plastics industry to improve the mechanical properties and reduce costs by serving as a filler. It is also used in the manufacturing of paints, where its fine particle size enhances pigment dispersion and provides smoother coatings.

Ultrafine calcium carbonate powder is crucial in the pharmaceutical industry for drug formulation. It allows for better dissolution rates, bioavailability, and uniformity of active pharmaceutical ingredients (APIs).

Our Projects

Copyright © ZENITH, All Right Reserved.