A gold ore processing plant is a complex and sophisticated industrial facility designed to extract and refine gold from raw ore. The process involves a series of stages, each designed to extract or refine the gold to a specific level of purity.

24 Online Service

Gold and gold ore are two closely related terms that are often used interchangeably. However, there is a significant difference between the two.

Gold is a dense, soft, yellow metal that is highly valued for its beauty and rarity. Gold is one of the most malleable and ductile metals, meaning it can be easily shaped into different forms without breaking. It is also an excellent conductor of electricity, making it a valuable material for electronic devices.

Gold is found in the earth’s crust and is usually found as small nuggets, flakes, or grains in riverbeds or buried underground. It is a relatively rare metal, with only about 200,000 tons of gold mined throughout history. Despite its rarity, gold is widely used in jewelry, currency, and investment.

Gold ore refers to the rock or mineral from which gold is extracted. Gold ore is a type of ore that contains gold and other minerals or elements in varying amounts. It is typically mined from underground or surface mines and processed to extract gold.

Gold ore is formed over millions of years through the geological process of sedimentation, metamorphism, and weathering. The gold in the ore is often in the form of microscopic particles or veins that are distributed throughout the rock. The amount of gold in the ore varies widely, ranging from a few grams per tonne to several hundred grams per tonne.

The primary difference between gold and gold ore is their composition. Gold is a pure metal with a specific atomic structure and chemical properties. Gold ore, on the other hand, is a mixture of minerals and metals that may contain gold in varying amounts.

Gold has a distinctive yellow color and a shiny metallic luster, while gold ore may have a variety of colors and textures depending on the minerals and metals present. Gold ore is often a dull gray or brown color and may be mixed with other materials such as quartz or pyrite.

Gold is highly valued for its rarity, beauty, and use in jewelry, currency, and investment. Gold ore, however, has little to no value until it is processed and the gold is extracted. The value of gold ore is determined by the amount of gold it contains and the cost of extracting the gold from the ore.

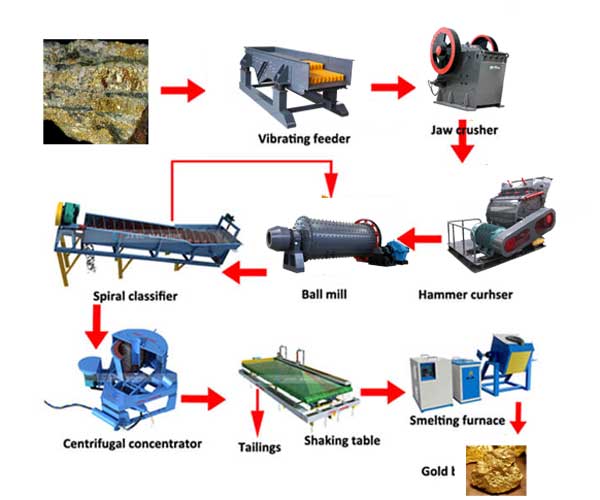

Gold is extracted from gold ore through a complex process that involves crushing, grinding, and chemical treatment to separate the gold from the other minerals and metals present in the ore. The process of extracting gold from ore can be time-consuming and costly, requiring specialized equipment and skilled workers.

Gold has many uses, including in jewelry, electronics, currency, and investment. Gold ore, however, has limited use until the gold is extracted. Once the gold is extracted, it can be used for the same purposes as pure gold.

Gold has been highly valued for its beauty and rarity since ancient times. Today, gold is still highly sought after for its use in jewelry, electronics, and currency. However, before gold can be used for these purposes, it must be extracted from the raw ore.

The first step in extracting gold from raw ore is to mine the ore. Gold ore can be found in many forms, including vein deposits, placer deposits, and deposits in sedimentary rocks. The type of deposit determines the mining method used. In general, underground mining is used for vein deposits, while surface mining is used for placer deposits and sedimentary rock deposits.

After the ore is mined, it is crushed into small pieces using crushers or stamp mills. Crushing the ore is necessary to release the gold particles from the surrounding rock. The ore is typically crushed to a fine powder, which is then mixed with water to create a slurry.

The slurry is then passed through a series of grinding mills, which further reduce the size of the particles. Grinding the ore is necessary to increase the surface area of the gold particles, making it easier for the gold to be extracted.

After the ore is ground, it is passed through a series of devices to separate the gold from the other minerals and metals present in the ore. One common method of gold extraction is gravity concentration. This involves using the difference in density between gold and other minerals to separate them. The slurry is passed through a series of shaking tables or centrifugal concentrators, which use gravity to separate the gold from the other minerals.

Another method of gold extraction is leaching. This involves using chemicals to dissolve the gold from the ore. One commonly used chemical for gold leaching is cyanide. The slurry is mixed with a cyanide solution, which dissolves the gold from the ore. The gold is then precipitated out of the solution using activated carbon or zinc dust.

Once the gold has been extracted from the ore, it is still not in a pure form. It must be refined to remove impurities and bring the gold to a marketable form. There are several methods of gold refining, including smelting, electrowinning, and precipitation.

Smelting: The gold is melted and separated from the impurities using a high-temperature furnace.

Electrowinning: An electrical current is passed through the gold solution, causing the gold to be deposited onto a cathode.

Precipitation: The gold is precipitated out of the solution using a chemical reaction or the addition of a precipitating agent.

The first stage in the gold ore processing plant process is crushing. The raw ore is transported to the processing plant and fed into a crushing machine. The machine breaks the ore down into small pieces, reducing it to a manageable size for further processing. The crushed ore is then transported to a grinding mill for further processing.

The second stage in the gold ore processing plant process is grinding. The crushed ore is fed into a grinding mill, which uses large steel balls or rods to break down the ore further. The grinding process reduces the ore to a fine powder, which is then mixed with water to create a slurry.

The third stage in the gold ore processing plant process is leaching. The slurry is passed through a series of tanks, where a chemical solution is added to dissolve the gold. The most commonly used chemical solution for gold leaching is cyanide. The cyanide solution reacts with the gold in the ore to form a soluble compound called gold cyanide. This compound is then extracted from the slurry and collected in a recovery tank.

The fourth stage in the gold ore processing plant process is carbon adsorption. In this stage, activated carbon is added to the gold cyanide solution. The activated carbon adsorbs the gold cyanide complex, removing it from the solution. The gold-laden activated carbon is then separated from the solution and transferred to a recovery tank.

The fifth stage in the gold ore processing plant process is elution. The gold-laden activated carbon is washed with a hot solution of cyanide and sodium hydroxide to remove any remaining impurities. The resulting solution, known as pregnant solution, is then sent to an electrowinning cell, where the gold is deposited onto a cathode.

The final stage in the gold ore processing plant process is smelting and refining. The gold deposited onto the cathode in the electrowinning cell is melted down and refined to remove any remaining impurities. The resulting gold is then poured into molds and formed into bars or other shapes for sale.

Gold mining has been a major industry for centuries, and it remains one of the most valuable and sought-after commodities in the world. However, the process of mining gold requires specialized equipment to extract and refine the metal.

One of the simplest and oldest methods of gold mining is panning. This technique involves using a pan to separate gold from sediment and other materials. The pan is filled with water and the mixture is agitated to help separate the gold. The gold settles to the bottom of the pan, while the lighter sediment is washed away.

Another early method of gold mining is sluicing. This involves using a channel or trough to direct water over gold-bearing gravel or rock. The water washes the material downstream, leaving the heavier gold behind in the sluice box.

Dredging involves using a floating device called a dredge to scoop up sediment from the bottom of a river or stream. The sediment is then processed to extract the gold. Dredging is a highly effective method of mining, but it can have significant environmental impacts.

Underground mining involves digging tunnels or shafts into the earth to reach gold deposits that are too deep to be accessed by surface mining. The tunnels or shafts are supported by specialized equipment, including timber supports and rock bolts. Underground mining can be dangerous and requires specialized training and equipment.

Surface mining involves using heavy equipment, such as bulldozers, excavators, and trucks, to remove the top layers of soil and rock to access gold deposits. This method is commonly used in open-pit mines, where the ore is close to the surface.

After the ore is extracted from the ground, it is transported to a processing facility where it is crushed and ground into a fine powder. This process helps to liberate the gold from the surrounding rock or mineral.

Leaching is a chemical process that involves the use of a solution to extract gold from ore. The solution, usually a cyanide solution, is applied to the ore and dissolves the gold. The gold is then recovered from the solution using activated carbon or zinc dust.

Once the gold is extracted from the ore, it must be refined to remove any impurities and bring it to a marketable form. This process can involve smelting, electrowinning, or precipitation, depending on the specific method used.

Material: Gold ore

Capacity: 360TPH

Daily Operation: 16h

Output Size: 0-12mm

Equipment: PE900 * 1200 jaw crusher (1 unit), HPT500 multi-cylinder hydraulic cone crusher (1 unit), HPT300 multi-cylinder hydraulic cone crusher (3 units)

Material: Gold ore

Daily Operation: 18h

Output Size: 0-12mm

Equipment: HPT500 multi-cylinder hydraulic cone crusher (1 unit), HPT300 multi-cylinder hydraulic cone crusher (two units)

Design Scheme

Project Location: West Africa

Material: Gold ore

Capacity: 2000TPD

Technological Process: Cyanidation

Material: Gold

Daily operation:10 hours;

Feeding size: below 400mm;

Output size: 0-16mm;

Equipment: PE600*900 jaw crusher, CSB160 spring cone crusher, CSD160 cone crusher, 2YA1860 vibrating screen.

Our Projects

Copyright © ZENITH, All Right Reserved.