The limestone powder making machine has revolutionized the construction industry by simplifying and optimizing the process of converting limestone into a fine powder. With its ability to produce high-quality limestone powder efficiently and consistently, this machine has become an indispensable tool for builders and engineers.

24 Online Service

Limestone is a versatile and widely used natural resource with various industrial applications. One of the most valuable forms of limestone is limestone powder, which finds application in industries like construction, agriculture, and chemical manufacturing. To establish a limestone powder factory, a range of specialized machinery is required to extract, process, and produce high-quality limestone powder.

The first step in establishing a limestone powder factory is to extract the raw material from a limestone quarry. Quarrying equipment plays a pivotal role in this process. Machinery such as excavators, loaders, and drilling rigs are utilized to remove the limestone from the earth’s crust. Excavators are used for large-scale excavation, while loaders assist in loading the extracted limestone onto trucks for transportation to the processing plant. Drilling rigs help in creating blast holes to break up the limestone into manageable pieces.

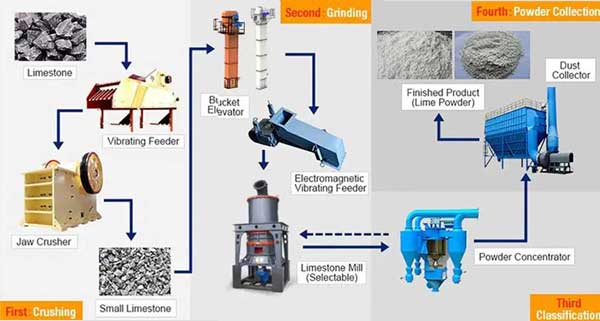

Once the limestone is extracted from the quarry, it needs to be crushed and ground into fine particles to produce limestone powder. Several machines are employed in this stage of the process:

The next crucial step in the limestone powder production process is calcination. Calcination involves heating the crushed limestone to high temperatures to drive off carbon dioxide and produce quicklime. Various types of equipment are used for this purpose:

After the limestone is calcined, it undergoes pulverization and powder handling processes to produce limestone powder of the desired fineness. The following machinery is typically employed:

In the realm of modern construction, limestone has emerged as a versatile and highly sought-after material. With its durability, aesthetics, and environmental benefits, limestone has become a popular choice for builders and architects. However, the effective utilization of limestone often requires it to be converted into a fine powder form. This is where the limestone powder making machine plays a pivotal role.

Limestone, a sedimentary rock composed primarily of calcium carbonate, possesses unique properties that make it an ideal construction material. Its natural composition grants it excellent strength, durability, and resistance to weathering. Furthermore, limestone is abundant and widely available, making it a sustainable choice for construction projects.

However, in order to unlock its full potential, limestone often needs to be processed into a fine powder. This powder form increases the surface area of limestone particles, allowing for better integration with other materials. Limestone powder enhances the workability and consistency of concrete and mortar mixes while providing improved mechanical properties and reducing the risk of cracking.

The limestone powder making machine, also known as a limestone grinding mill, is a technologically advanced and innovative solution designed specifically for processing limestone into fine powder. This machine employs mechanical force and chemical reactions to pulverize limestone, transforming it into a high-quality powder suitable for various applications.

The working principle of the limestone powder making machine involves several stages. Firstly, large pieces of limestone are crushed into smaller particles by a jaw crusher or a hammer crusher. These smaller fragments are then fed into the grinding mill, where they are subjected to high-speed rotation and grinding media, such as steel balls or ceramic beads. The intense grinding action breaks down the limestone particles further, resulting in a fine powder.

The limestone powder making machine offers numerous advantages that make it an indispensable tool in the construction industry.

Firstly, it enables efficient and cost-effective limestone powder production. The machine can process large quantities of limestone quickly, reducing the time and labor required for manual processing.

Secondly, the machine ensures consistent and uniform particle size distribution, resulting in high-quality limestone powder. This consistency is crucial for achieving optimal performance in concrete, mortar, and other applications.

Furthermore, the limestone powder making machine provides versatility in particle size customization. By adjusting the grinding parameters, the machine can produce fine or coarse limestone powder to meet specific project requirements.

To harness the full potential of limestone, it often needs to be processed into fine powder form. This is where limestone grinding machines come into play, providing efficient and precise grinding solutions for powder production.

Limestone powder has numerous applications, ranging from construction materials to industrial chemicals and agriculture. In the construction industry, it is used as a key ingredient in cement, concrete, and mortar. Limestone powder enhances the strength and durability of these materials while also reducing costs. Additionally, it acts as a filler material in asphalt and contributes to the stability and longevity of roads.

In the agriculture sector, limestone powder plays a crucial role in soil amendment. It helps to balance soil pH levels, neutralizing acidity and improving the overall fertility of the soil. By providing essential nutrients such as calcium and magnesium, limestone powder promotes healthy plant growth and crop yield. Furthermore, it serves as a component in animal feed, contributing to the proper development of livestock and poultry.

To meet the growing demand for high-quality limestone powder, specialized grinding machines have been developed. These machines are designed to grind limestone into fine particles of various sizes, depending on the specific requirements of the end-user. The limestone grinding process involves crushing, grinding, and classifying the raw limestone into different particle sizes.

The first step in the process is the primary crushing of limestone using a jaw crusher or impact crusher. The crushed limestone is then transported to the grinding mill for grinding. In the grinding mill, limestone particles are ground by a combination of impact and abrasion forces generated by the grinding media such as balls or rods. The size of the final ground limestone powder can be adjusted by changing the grinding parameters, such as the grinding time, speed, and media size.

Modern limestone grinding machines are equipped with advanced control systems that allow operators to optimize the grinding process for maximum efficiency and quality. These machines can handle large quantities of limestone and operate continuously for extended periods, ensuring a steady supply of high-quality limestone powder. Some grinding machines also incorporate air classifiers, which separate the fine particles from the coarse ones, resulting in a more uniform and consistent product.

The choice of limestone grinding machine depends on various factors, including the desired particle size, production capacity, energy consumption, and cost considerations. There are several types of grinding machines available in the market, including ball mills, Raymond mills, vertical roller mills, and ultrafine mills. Each type has its advantages and limitations, and the selection should be based on careful evaluation of the specific requirements and conditions.

Ball mills are commonly used for coarse grinding and can produce relatively large particles. Raymond mills, on the other hand, are suitable for fine grinding and can achieve a narrower particle size distribution. Vertical roller mills offer high energy efficiency and can handle both coarse and fine grinding. Ultrafine mills, as the name suggests, are designed to produce ultrafine particles and are ideal for applications requiring extremely fine limestone powder.

In addition to selecting the right grinding machine, it is essential to consider the overall system design, including the feeding and conveying of limestone, dust collection, and product storage. Efficient material handling and dust control systems are crucial to ensure a clean and safe working environment and prevent product contamination.

Furthermore, it is important to emphasize the importance of regular maintenance and proper operation of limestone grinding machines. Routine inspections, lubrication, and timely replacement of worn parts can significantly extend the lifespan of the equipment and maintain its optimal performance. Additionally, operators should follow the recommended safety guidelines and receive proper training to operate the machines safely and efficiently.

One of the most lucrative uses of limestone is in the production of limestone powder, which finds extensive usage in construction materials, agriculture, chemical industries, and more.

Before venturing into any business, thorough market research is crucial. Evaluate the demand and potential customers for limestone powder in your target region. Identify key competitors, pricing strategies, and market trends to ensure there is a viable market for your product.

Once you have a clear understanding of the market, develop a comprehensive business plan. Outline your goals, target market, marketing strategies, financial projections, and necessary resources. This plan will serve as a roadmap for your venture and help attract investors or secure financing.

Selecting the right location for your limestone powder processing plant is vital. Look for areas with abundant limestone deposits and easy access to transportation routes. The proximity to raw materials and potential customers will significantly impact your operational costs and profitability.

Ensure that you obtain the necessary permits and licenses from local authorities. Environmental regulations, zoning restrictions, and health and safety standards should be thoroughly researched and adhered to. Engage with the relevant government agencies to understand the requirements and streamline the permit application process.

Limestone is the primary raw material for producing limestone powder. Identify reliable limestone suppliers in your region and establish long-term partnerships. Evaluate the quality, consistency, and pricing of the limestone to ensure a steady supply chain.

Conduct thorough testing and analysis of the limestone to ascertain its suitability for powder production. Factors such as chemical composition, particle size distribution, and moisture content should be considered to produce high-quality limestone powder.

Investing in the right machinery and equipment is crucial for a smooth limestone powder processing operation. Some essential equipment includes crushers, ball mills, classifiers, dust collectors, and packaging machines. Consult with industry experts or equipment suppliers to determine the most suitable machinery for your specific requirements.

Consider factors such as production capacity, energy efficiency, maintenance requirements, and operational costs when selecting equipment. It is advisable to invest in modern and efficient machinery to optimize productivity and minimize downtime.

The production process of limestone powder involves several stages, including crushing, grinding, classification, and packaging. Develop a systematic workflow that ensures efficient processing and consistent product quality.

Implement a robust quality control system to monitor the various parameters of the limestone powder, such as particle size, purity, and moisture content. Regular testing and analysis will help maintain product consistency and meet customer expectations.

Create a strong marketing strategy to promote your limestone powder and attract customers. Identify potential buyers in construction, agriculture, chemical, and other relevant industries. Establish connections with contractors, distributors, and wholesalers who can help you reach a wider customer base.

Utilize various marketing channels, including online platforms, trade shows, and industry publications, to showcase your product’s features and advantages. Highlight the quality, consistency, and competitive pricing of your limestone powder to differentiate yourself from competitors.

To thrive in the limestone powder processing industry, it is essential to continuously improve and expand your operations. Stay updated with the latest technological advancements and industry trends. Invest in research and development to explore innovative uses of limestone powder and diversify your product range.

Monitor customer feedback and adapt your processes accordingly to meet their evolving needs. Expand your production capacity as demand grows, ensuring a steady supply to maintain customer satisfaction.

Daily operation: 10 hours;

Feeding-in material: limestone;

Grinding particle size: <=35mm;

Finished product: 325 mesh.

Equipment:a set of MTW110 and a set of MTW138

Daily Operation: 10h

Material: Limestone

Input Size: 0-40mm

Output Size: 180mesh, 250mesh

Daily Operation: 10h

Material: Limestone

Input Size: 0-40mm

Output Size: 250mesh

Equipment: 2 sets of MTW175 European Grinding Mills

Daily Operation: 24h

Material: Limestone

Input Size: 0-35mm

Output Size: 250-325mesh

Equipment: MTW175 European Grinding Mills

Our Projects

Copyright © ZENITH, All Right Reserved.