Portable crushers have revolutionized the crushing industry by offering a practical and efficient solution to tackle large-scale crushing jobs. Their ability to be easily transported and set up on-site provides convenience and flexibility, while their cost-effectiveness and environmental friendliness make them an attractive option for businesses.

24 Online Service

Mineral processing is a fundamental aspect of the mining industry, aiming to extract valuable minerals from their ores efficiently. Among the various stages involved in mineral processing, crushing plays a vital role in the overall process. By reducing the size of the ore particles, crushing facilitates subsequent steps such as grinding, flotation, and leaching, enabling the extraction of valuable metals and minerals.

Crushing is primarily performed to liberate valuable minerals from the gangue (unwanted material) present in the ore. Ores extracted from mines often contain a mixture of valuable minerals and worthless rocks or minerals. Through the process of crushing, the ore is reduced to smaller sizes, allowing the liberation of the valuable minerals from the gangue. Liberation is achieved when the valuable mineral particles are separated from the non-valuable ones, making them available for further processing.

Crushing plays a crucial role in increasing the surface area of the ore particles. By reducing the size of the ore, the available surface area for chemical reactions is significantly enhanced. This increased surface area facilitates the interaction between the ore particles and reagents during subsequent mineral processing steps. The exposure of a larger surface area ensures better contact between the minerals and chemicals, promoting efficient extraction and separation of valuable elements.

The efficiency of separation processes, such as flotation and magnetic separation, greatly depends on the particle size of the ore. Crushing aids in achieving the desired particle size, thereby enhancing the effectiveness of separation techniques. Smaller particle sizes enable improved separation efficiency since it is easier to distinguish between minerals based on their physical and chemical properties. Crushing helps create a more uniform particle size distribution, making it easier to separate the valuable minerals from the gangue during subsequent processing steps.

Crushing also plays a critical role in preparing the ore for grinding. Grinding is a size reduction process that further reduces the crushed ore particles to finer sizes. It is an energy-intensive process, and the particle size distribution of the crushed ore significantly impacts the efficiency of grinding operations. Properly crushed ore with a well-controlled particle size distribution allows for better control over grinding parameters, ensuring optimal grinding performance and reducing energy consumption.

Efficiency and cost-effectiveness are crucial factors in mineral processing operations. Crushing helps achieve both by improving the overall efficiency of the mineral extraction process. When ores are crushed to the desired size, subsequent processing steps become more efficient, reducing the overall processing time and energy consumption. This leads to cost savings and increased profitability for mining companies.

Efficient crushing techniques contribute to resource conservation and minimize the environmental impact of mineral processing operations. By reducing the size of the ore particles, the amount of ore required for processing is reduced. This decreases the overall footprint of mining activities, conserving valuable resources. Additionally, efficient crushing reduces the generation of waste material, leading to reduced environmental pollution and land disturbance.

Portable rock crushers have revolutionized the mining and construction industries by providing a versatile and efficient solution for crushing rocks and minerals on-site. These compact machines offer the flexibility to move easily between job sites, reducing the need for transportation and allowing for increased productivity.

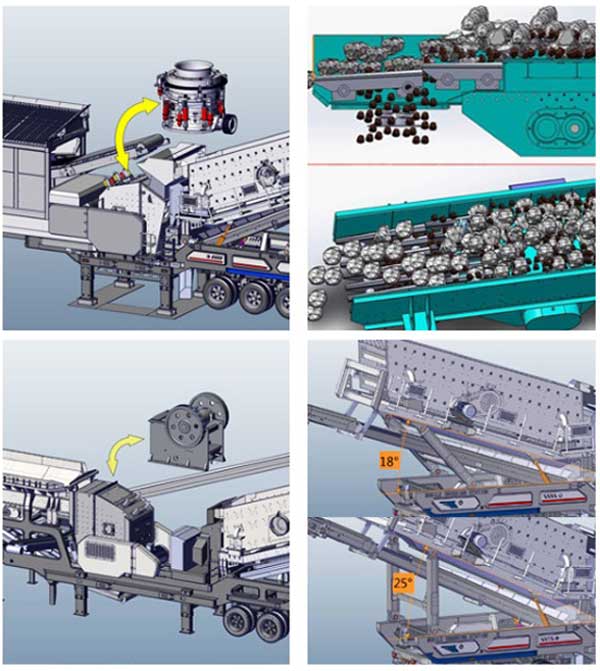

Portable rock crushers consist of several essential components that work together to efficiently crush rocks and minerals. These include:

The working principles of portable rock crushers vary depending on the type of crusher being used. However, they generally follow these basic steps:

In the construction and mining industries, the demand for efficient and mobile crushing equipment has been steadily rising. The ability to move crushing machinery from one location to another quickly and easily has proven to be a significant advantage for many contractors and operators. However, this convenience comes at a cost. Portable crushing equipment often requires more real estate compared to stationary counterparts.

Portable crushing equipment, such as mobile jaw crushers, impact crushers, and cone crushers, offers numerous benefits to construction and mining projects. Its mobility allows contractors to bring the crushing equipment closer to the material source, reducing the need for excessive transportation. Additionally, these machines are designed to efficiently process various materials, including concrete, asphalt, and natural rock, providing contractors with the flexibility to tackle different types of projects.

One of the primary reasons portable crushing equipment requires more real estate is the need for supporting infrastructure. Unlike stationary crushers, which are permanently installed in one location, portable equipment must be set up and dismantled for each project. This process involves assembling various components, such as the crusher, conveyors, and screening units, which require additional space for storage and maintenance. Furthermore, portable equipment often relies on generators or power sources, which require adequate space for operation and fuel storage.

Another factor contributing to the larger footprint of portable crushing equipment is the need for accessibility and safety considerations. To ensure efficient operation and maintenance, these machines require ample space around them. Technicians need room to access key components for inspections, repairs, and general maintenance. Additionally, safety regulations often dictate that equipment should be positioned with sufficient clearance to prevent accidents and allow for safe operation. These factors necessitate a more extensive work area compared to stationary crushers.

Moving from one location to another can be a daunting task, especially when you have large amounts of construction debris or aggregates to transport. Traditional methods of hauling materials can be time-consuming, costly, and require significant manpower. However, with the advent of portable crushers, the process of moving construction materials has been revolutionized. A portable crusher offers a convenient and efficient solution that allows you to move less often and save both time and resources.

A portable crusher is a compact machine designed to crush and recycle materials on-site. It can be easily transported to different locations, making it an ideal choice for construction projects that require frequent relocation. With a portable crusher, you can process materials directly at the job site, eliminating the need to transport them to a centralized crushing facility. This not only saves time but also reduces transportation costs and minimizes the environmental impact associated with long-distance hauling.

One of the key advantages of a portable crusher is its versatility. It can handle a wide range of materials, including concrete, asphalt, rock, and gravel. This means that whether you’re demolishing a building, renovating a road, or working on a landscaping project, a portable crusher can effectively crush and recycle the materials, turning them into usable products. The crushed materials can be used as a base for new construction, as fill material, or even sold to generate revenue.

The mobility of a portable crusher is a game-changer for contractors and construction companies. Instead of relying on multiple crushing sites or transporting materials back and forth, a portable crusher allows you to set up a crushing operation wherever you need it. This flexibility improves productivity and efficiency, as you can quickly move the crusher to different areas of the job site as needed. It also enables you to respond swiftly to changes in project requirements without incurring delays or additional expenses.

In addition to its mobility, a portable crusher offers significant cost savings. Traditional crushing methods involve transporting materials to a fixed crushing facility, which can be expensive, especially when dealing with large volumes of materials. The cost of transportation, labor, and equipment can quickly add up, putting a strain on project budgets. With a portable crusher, you eliminate the need for transportation and associated costs. Instead, you can crush materials on-site, reducing expenses and maximizing your return on investment.

Moreover, using a portable crusher can have positive environmental implications. By crushing and recycling materials on-site, you reduce the amount of waste sent to landfills, thus minimizing your carbon footprint. Additionally, the use of recycled materials can contribute to sustainable construction practices. Reusing crushed materials as a base for new construction reduces the need for aggregates, conserving natural resources and promoting a circular economy. With increasing emphasis on environmental responsibility, a portable crusher aligns with the goals of green construction and sustainable development.

The convenience and efficiency offered by a portable crusher extend beyond construction projects. It is also a valuable asset for quarry operators and mining companies. Quarry operations often involve moving heavy machinery and processing equipment from one area to another. A portable crusher simplifies this process by allowing the crushing operation to be brought directly to the source of the materials. This streamlines the workflow, reduces downtime, and enhances overall operational efficiency.

Traditional crushing methods often pose logistical challenges, especially when dealing with large-scale jobs. That’s where portable crushers come into play, revolutionizing the crushing industry by providing a versatile and efficient solution to tackle these demanding tasks.

A portable crusher is a mobile machine that can be transported to different job sites, allowing for on-site crushing of materials. Unlike stationary crushers, which are permanently installed in a specific location, portable crushers offer flexibility and convenience. They can be easily moved from one place to another, reducing the need for multiple crushing stations and minimizing transportation costs.

One of the key advantages of portable crushers is their ability to handle large-scale crushing jobs. These machines are designed to process vast quantities of materials, ranging from hard rocks to demolition debris. By employing powerful jaws or impactors, they can break down even the toughest materials into smaller, more manageable sizes. This capability makes portable crushers ideal for projects that require significant amounts of crushed materials, such as highway construction, large-scale infrastructure developments, and mining operations.

Moreover, portable crushers provide a cost-effective solution for crushing operations. Traditional crushing methods often involve transporting materials to a stationary crusher, incurring additional expenses for fuel, labor, and equipment. With portable crushers, the crushing process takes place on-site, eliminating the need for material transportation. This not only saves time but also reduces costs, making it an attractive option for businesses looking to optimize their operations.

Furthermore, portable crushers offer enhanced productivity and efficiency. These machines are equipped with advanced features that streamline the crushing process, resulting in higher throughput and faster production rates. Many portable crushers are designed with automation systems that optimize performance and ensure consistent product quality. This level of automation reduces the dependency on manual labor, minimizing the risk of human error and improving overall operational efficiency.

In the world of construction and mining, having the right equipment can make a significant difference in the efficiency and success of your operations. One crucial piece of machinery that plays a vital role in many projects is a portable rock crusher. These compact and mobile crushers are designed to break down large rocks into smaller, more manageable sizes, allowing for easier transportation and processing. However, selecting the right portable rock crusher for your operations requires careful consideration and evaluation of several factors.

Before diving into the specifics of different rock crushers, it is essential to understand the purpose and application of the equipment in your operations. Are you primarily crushing stones for road construction, quarrying materials for aggregate production, or processing ore for mining operations? Each of these applications has unique requirements, such as the desired output size, throughput capacity, and material hardness. By defining your purpose and application, you can narrow down the options and focus on crushers that meet your specific needs.

The primary advantage of a portable rock crusher is its mobility, allowing you to take the equipment directly to the job site. However, not all portable crushers offer the same level of mobility and transportability. Consider the size and weight of the crusher, as well as the ease of set-up and dismantling. If your operations involve frequent relocation or require moving the crusher through challenging terrains, opting for a compact and lightweight model with a track-mounted design might be the best choice.

The crushing capacity and efficiency of a portable rock crusher play a crucial role in determining its suitability for your operations. The crusher should be capable of processing the desired amount of material within a given timeframe. Consider factors such as the feed size, output size, and production rate required for your project. Additionally, evaluate the power and performance of the crusher, including the motor power, crushing force, and the ability to handle various types of rocks. Efficient crushing reduces downtime and maximizes productivity, ensuring a higher return on investment.

Maintenance and serviceability are vital aspects to consider when selecting a portable rock crusher. Look for a model that offers ease of maintenance, with convenient access to key components for inspection, repair, and replacement. Consider the availability of spare parts and the manufacturer’s reputation for providing reliable customer support. A crusher with good serviceability features can minimize downtime and keep your operations running smoothly.

Safety should always be a top priority in any industrial operation. When evaluating portable rock crushers, consider the safety features incorporated into the design. Look for features such as automatic overload protection, emergency stop buttons, and safety guards. A crusher with advanced safety features can protect the operators and reduce the risk of accidents, promoting a safer working environment.

In today’s environmentally conscious world, it is essential to consider the environmental impact of your operations. Evaluate the crusher’s noise levels and emissions, ensuring compliance with local regulations and standards. Look for models equipped with advanced dust suppression systems to minimize dust generation during the crushing process. By selecting an environmentally friendly rock crusher, you can reduce your carbon footprint and contribute to sustainable practices.

Last but not least, consider the cost and return on investment of the portable rock crusher. While the initial purchase price is an important factor, it is equally crucial to evaluate the crusher’s long-term operational costs, including maintenance, fuel consumption, and spare parts. Assess the expected lifespan of the equipment and its potential resale value. A thorough cost analysis will help you make an informed decision and choose a rock crusher that offers the best value for your money.

Our Projects

Copyright © ZENITH, All Right Reserved.