Limestone is a sedimentary rock composed mostly of calcium carbonate (CaCO3) in the form of the mineral calcite. It is formed from the accumulation of shells, coral, and other marine debris, as well as the precipitation of calcium carbonate from water.

24 Online Service

Limestone is often gray, but it can also be white, yellow, or brown in color, and it is typically very dense and hard. It has been used as a building material for centuries, and is often used in architecture and construction due to its durability and attractive appearance. Limestone is also used in the production of cement, as a soil conditioner, and in various industrial processes.

Limestone powder is a fine white or off-white powder that is produced by crushing and grinding limestone rock. It is also known as calcium carbonate powder or pulverized limestone, and it has a variety of uses in different industries.

In agriculture, limestone powder is used as a soil amendment to increase the pH level of acidic soils, which can improve crop yields. In the construction industry, it is used as a filler or pigment in concrete and other building materials.

Limestone powder is also used in the production of cosmetics, such as toothpaste and cosmetics, as well as in the manufacture of paper, plastics, and rubber. It is also used as a food additive, particularly in the baking industry, as a source of calcium. Limestone powder is generally considered safe for these uses, but it is important to use caution when handling and storing it, as it can be irritating to the eyes, skin, and respiratory system if inhaled.

Limestone is a sedimentary rock that contains calcium carbonate, a mineral that is essential for a variety of industrial and agricultural applications. To make use of the material, it needs to be crushed into small pieces. The limestone crushing process is a crucial aspect of cement production, as it is responsible for the quality and consistency of the final product.

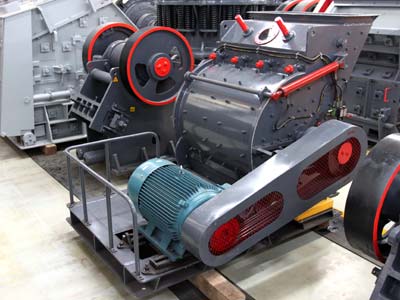

The limestone crushing process is an important aspect of cement production. Limestone is the main raw material for cement production, and it needs to be crushed by jaw crusher or impact crusher to reduce the size to about 6-12mm. Limestone is then mixed with clay or shale in a ball mill to form a slurry or paste, which is then fed into a rotary kiln, where it is heated to a temperature of around 1,450 degrees Celsius. This process is known as calcination, and it converts the limestone into quicklime (CaO).

The quicklime is then cooled and ground into a fine powder, which is known as Portland cement. Portland cement is a hydraulic binder that hardens when mixed with water, forming a strong and durable material that is used in a variety of construction applications, such as buildings, bridges, and roads.

The limestone crushing process is crucial for the quality and consistency of the final product. If the limestone is not properly crushed and mixed with clay or shale, the resulting Portland cement may have inconsistent properties and strength, which can lead to safety issues and structural failures.

The limestone crushing process is a multi-stage process that involves crushing, grinding, and screening. Here is a brief overview of each stage:

The limestone crushing process can be challenging due to several factors, including the hardness of the limestone, the size of the particles, and the variability of the material. Here are some of the challenges that need to be addressed:

Addressing these challenges requires careful planning, equipment selection, and process optimization. For example, selecting crushers and mills that are designed for high abrasiveness can help to prolong their lifespan and reduce maintenance costs. Using screens and classifiers can help to ensure a consistent particle size, while controlling the process parameters can help to optimize the energy consumption and reduce emissions.

Grinding limestone is the process of reducing the size of limestone particles, typically to a fine powder. The process is accomplished by using a variety of different mills, including ball mills, roller mills, and hammer mills. These machines operate by applying force to the limestone, causing it to break down into smaller pieces.

The first step in the grinding process is to crush the limestone into a size suitable for the mill. This is typically done using a crusher, which can be a jaw crusher or impact crusher. Once the limestone has been crushed, it is then fed into the mill, where it is ground into a fine powder.

There are several different types of mills that can be used to grind limestone, each with its own unique characteristics. Ball mills are the most commonly used type of mill for grinding limestone. They operate by rotating the cylinder containing the limestone, which then causes the balls within the cylinder to fall and strike the limestone, breaking it down into smaller particles. Roller mills operate in a similar manner, but instead of balls, they use rollers to crush the limestone. Hammer mills, on the other hand, use hammers to crush the limestone into smaller pieces.

The choice of mill used to grind limestone depends on a variety of factors, including the desired particle size, the hardness of the limestone, and the amount of limestone that needs to be ground. For example, if a large amount of limestone needs to be ground to a fine powder, a ball mill may be the best choice, as it is capable of processing large quantities of material quickly and efficiently.

Grinding limestone is an important process that plays a critical role in many industries. It allows limestone to be broken down into a fine powder that can be used for a variety of different applications. Whether it is being used to improve the strength of concrete or as a soil conditioner, limestone powder is a valuable resource that can help to improve the quality of many different products.

When it comes to grinding limestone, there are a few different machines that can be used to achieve the desired result. The choice of machine will depend on a variety of factors, including the hardness of the limestone, the desired particle size, and the production capacity required.

Raymond mill, also known as Raymond roller mill, is a commonly used machine for grinding limestone. This machine is equipped with a grinding roller that rotates around a vertical axis and a grinding ring that is fixed to the inner wall of the mill. The limestone is fed into the mill through a hopper and is ground between the grinding roller and the grinding ring. The resulting powder is then collected in a cyclone separator or bag filter.

The main advantage of the Raymond mill is its high efficiency. It can produce fine and ultra-fine powders with a particle size of up to 325 mesh. This machine is also relatively easy to operate and maintain. However, its main drawback is its high energy consumption, which can lead to high operating costs.

The ball mill is another commonly used machine for grinding limestone. It works in a similar way to the Raymond mill, but instead of a grinding roller, it uses a rotating drum filled with steel balls. The limestone is fed into the drum and is ground by the impact of the steel balls as they tumble around. The resulting powder is then collected in a cyclone separator or bag filter.

The main advantage of the ball mill is its versatility. It can be used for both dry and wet grinding, and it can produce a wide range of particle sizes. This machine is also relatively inexpensive and easy to maintain. However, its main drawback is its relatively low efficiency. It requires a large amount of energy to operate, and it can be difficult to achieve a fine particle size with this machine.

The vertical roller mill is a relatively new machine that has become increasingly popular in recent years. It works by grinding the limestone between a rotating grinding table and a set of grinding rollers. The limestone is fed into the mill through a central chute and is ground by the rollers as it passes over the grinding table. The resulting powder is then collected in a cyclone separator or bag filter.

The main advantage of the vertical roller mill is its high efficiency. It can produce fine and ultra-fine powders with a particle size of up to 10 microns. This machine is also relatively easy to operate and maintain. However, its main drawback is its high cost. It is typically more expensive than other machines, and it can be difficult to justify the investment unless very fine particle sizes are required.

The hammer mill is a machine that uses a series of hammers to grind the limestone into a fine powder. The hammers are mounted on a rotating shaft and are designed to break up the limestone into smaller pieces. The resulting powder is then collected in a cyclone separator or bag filter.

The main advantage of the hammer mill is its low cost. It is typically one of the least expensive machines for grinding limestone. It is also relatively easy to operate and maintain. However, its main drawback is its low efficiency. It requires a large amount of energy to operate, and it can be difficult to achieve a fine particle size with this machine.

The ultrafine mill is a machine that is designed to produce ultra-fine powders with a particle size of up to 2500 mesh. It works by grinding the limestone between a set of grinding rollers and a grinding ring. The limestone is fed into the mill through a central chute and is ground by the rollers as it passes over the grinding mill.

Our Projects

Copyright © ZENITH, All Right Reserved.