Construction aggregate refers to a category of materials that are commonly used in construction projects. These materials are typically composed of crushed stone, gravel, sand, recycled concrete, or other similar materials. Construction aggregates are commonly used as a base material for roads, foundations, and building structures.

24 Online Service

There are several types of construction aggregates, each with unique properties and uses. For example, fine aggregates such as sand are commonly used in concrete production and as a bedding material for pipes and utilities. Coarse aggregates, such as crushed stone and gravel, are often used as a base material for roadways and in the construction of building foundations.

The selection of the appropriate type of construction aggregate will depend on the specific requirements of the project. Factors such as load-bearing capacity, durability, and cost will all play a role in the selection process. Properly selecting and using construction aggregate is critical to the success of any construction project, as it can greatly impact the overall strength and stability of the final structure.

Aggregates are an essential component of construction materials that are widely used in various infrastructure and building projects. They are the primary building blocks of concrete, and their characteristics influence the strength, durability, and performance of concrete.

Coarse aggregates are the largest type of aggregates used in construction. They are typically larger than 4.75 mm in diameter and can be made from a variety of materials, such as crushed stone, gravel, and recycled concrete. These aggregates are used in the production of concrete for structural applications such as foundations, columns, and beams.

The properties of coarse aggregates depend on their source and production method. Crushed stone, for instance, is a hard, durable, and angular material that provides good resistance to wear and erosion. Gravel, on the other hand, is a rounded material that is softer than crushed stone but provides good drainage properties. Recycled concrete is another popular source of coarse aggregates, as it is a sustainable option that helps reduce waste.

Fine aggregates are smaller than coarse aggregates, typically ranging from 0.075 mm to 4.75 mm in diameter. They are usually made from natural sand, crushed stone sand, or crushed gravel sand. Fine aggregates are primarily used in the production of concrete and mortar for non-structural applications such as plastering, flooring, and masonry work.

The properties of fine aggregates are important in determining the workability and strength of concrete. Natural sand is the most commonly used fine aggregate, as it provides good workability and is readily available in most regions. Crushed stone sand and crushed gravel sand are alternatives to natural sand, which may be preferred for certain applications due to their specific properties.

Lightweight aggregates are used in concrete to reduce its weight while maintaining its strength and durability. These aggregates are typically made from materials such as expanded shale, clay, or slate that are heated to create porous, lightweight particles. They are used in the production of structural and non-structural concrete, as well as in the construction of lightweight blocks and precast elements.

The properties of lightweight aggregates are different from those of conventional aggregates. They have a lower density, higher absorption, and lower strength compared to normal-weight aggregates. However, they also have lower thermal conductivity and higher fire resistance, making them suitable for specific applications such as insulation and fireproofing.

Decorative aggregates are used primarily for aesthetic purposes in landscaping, garden design, and decorative concrete. These aggregates are available in a wide range of colors, shapes, and sizes, and can be made from materials such as crushed glass, recycled rubber, or colored stones.

The properties of decorative aggregates vary depending on their source and production method. Crushed glass, for instance, provides a unique, shimmering effect that can add a touch of glamour to any design. Recycled rubber aggregates, on the other hand, are a sustainable option that can be used to create safe and slip-resistant surfaces in public spaces.

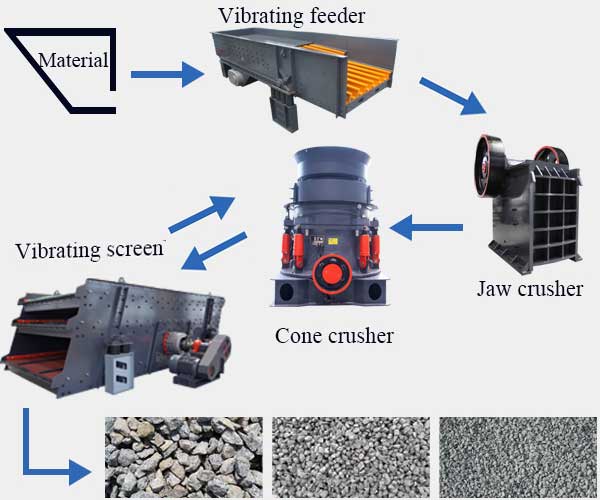

The process of crushing aggregates involves the use of specialized machinery to break these materials down into smaller pieces that are suitable for use in construction projects.

The process of crushing aggregates requires the use of specialized machinery, including crushers, screens, and conveyors. Crushers are the primary equipment used in the crushing process, and they come in various types, including jaw crushers, cone crushers, impact crushers, and gyratory crushers. Each type of crusher has its unique features, but they all work to break down large rocks into smaller pieces that can be used in construction projects.

Screens are used to separate the crushed aggregates by size, ensuring that the final product meets the desired specifications. Conveyors are used to transport the crushed aggregates from one stage of the crushing process to another, ensuring that they are moved efficiently and without any loss.

There are two main types of crushing methods used in the process of crushing aggregates: compression crushing and impact crushing.

Compression crushing involves applying a force to the material to break it down into smaller pieces. This is typically done using a jaw crusher or a cone crusher. In a jaw crusher, the material is fed into a chamber that contains a fixed jaw and a moving jaw. The moving jaw exerts a force on the material, crushing it against the fixed jaw until it is small enough to pass through the opening at the bottom of the chamber.

In a cone crusher, the material is fed into a chamber that contains a cone-shaped crushing head. The crushing head rotates, exerting a force on the material and crushing it against the stationary wall of the chamber. The crushed material is then discharged through an opening at the bottom of the chamber.

Impact crushing involves striking the material with a high-speed rotating rotor. This is typically done using an impact crusher. In an impact crusher, the material is fed into a chamber that contains a rotating rotor with hammers or blow bars. The material is struck by the hammers or blow bars, breaking it down into smaller pieces. The crushed material is then discharged through an opening at the bottom of the chamber.

Crushed aggregates are used in a variety of construction projects, including road construction, building construction, and landscaping. They are used as a base material for roads and driveways, providing a stable foundation that can support heavy loads. They are also used in the construction of buildings, providing a durable and long-lasting material for walls, floors, and foundations. In landscaping, crushed aggregates are used to create decorative features, such as pathways, retaining walls, and garden beds.

Crushers are machines used to break down large rocks, stones, and other materials into smaller pieces. They are used in various industries, such as mining, construction, and recycling. Crushers are essential in the construction industry, as they are responsible for crushing and processing aggregate materials.

Jaw crushers are one of the most commonly used machines for crushing aggregate materials. They are ideal for crushing hard materials, such as granite, and are used in the construction industry for primary crushing. Jaw crushers consist of two plates, one stationary and one movable, with the movable plate moving back and forth to crush the materials.

The stationary plate is fixed in place, while the movable plate moves back and forth. When the movable plate moves towards the stationary plate, the materials are crushed between the two plates. The crushed materials then pass through a series of screens to separate them by size.

Impact crushers are another type of machine used to crush aggregate materials. They are ideal for crushing softer materials, such as limestone, and are commonly used in the construction industry for secondary crushing. Impact crushers consist of a rotor, a set of blow bars, and an impact plate.

The rotor rotates at high speed, causing the blow bars to strike the materials. The materials are then thrown against the impact plate, where they are crushed and broken into smaller pieces. The crushed materials then pass through a series of screens to separate them by size.

Cone crushers are another type of machine used to crush aggregate materials. They are ideal for crushing harder materials, such as granite, and are commonly used in the construction industry for tertiary crushing. Cone crushers consist of a cone-shaped mantle that rotates eccentrically inside a concave bowl.

As the mantle rotates, it creates a crushing action, causing the materials to be crushed between the mantle and the concave bowl. The crushed materials then pass through a series of screens to separate them by size.

Gyratory crushers are another type of machine used to crush aggregate materials. They are ideal for crushing large materials, such as boulders, and are commonly used in the mining industry. Gyratory crushers consist of a cone-shaped mantle that rotates eccentrically inside a concave bowl.

As the mantle rotates, it creates a crushing action, causing the materials to be crushed between the mantle and the concave bowl. The crushed materials then pass through a series of screens to separate them by size.

An aggregate crushing plant is a vital part of any construction project. It is important to understand the components that make up this plant to ensure it operates efficiently and effectively. The major components of an aggregate crushing plant include a primary crusher, secondary crusher, tertiary crusher, screen, and conveyors. These components work together to achieve the desired results for the construction project.

The primary crusher is the first step in the aggregate crushing process. It reduces large rocks or ores into smaller pieces that can be processed further. This component is typically a jaw crusher, which is designed to take large rocks and break them down into smaller pieces. The primary crusher is crucial because it sets the stage for the rest of the crushing process. If it does not work properly, it can cause delays and costly repairs.

The secondary crusher comes into play once the primary crusher has done its job. This component takes the smaller pieces produced by the primary crusher and further reduces their size. The secondary crusher can be a cone crusher, impact crusher, or another type of crusher. The choice of secondary crusher depends on the type of material being crushed and the desired output size. It is important to select a secondary crusher that is capable of handling the type of material being processed and producing the desired output.

The tertiary crusher is the final stage in the aggregate crushing process. It is used to further reduce the size of the material, producing the final product size. The tertiary crusher can be a cone crusher, impact crusher, or another type of crusher. The choice of tertiary crusher depends on the type of material being crushed and the desired output size. It is important to select a tertiary crusher that is capable of handling the type of material being processed and producing the desired output.

The screen is a critical component of the aggregate crushing plant. It is used to separate the crushed material into different sizes. The screen can be a vibrating screen, a horizontal screen, or another type of screen. The choice of screen depends on the type of material being processed and the desired output size. It is important to select a screen that is capable of handling the type of material being processed and producing the desired output.

The conveyors are used to transport the material from one component of the aggregate crushing plant to another. There are many different types of conveyors, including belt conveyors, screw conveyors, and pneumatic conveyors. The choice of conveyor depends on the type of material being transported and the distance it needs to travel. It is important to select a conveyor that is capable of handling the type of material being transported and the desired output.

In addition to these major components, there are other components that make up an aggregate crushing plant. These include the control panel, dust suppression system, and storage bins. The control panel is used to monitor and control the operation of the plant. The dust suppression system is used to control the amount of dust produced during the crushing process. The storage bins are used to store the crushed material before it is transported to its final destination.

Mobile aggregate crushing plants are becoming increasingly popular as a way to process and recycle materials on-site, especially for construction and demolition sites. These plants allow contractors and builders to crush and process materials into usable products, which can then be sold or reused in construction projects. In this article, we’ll discuss what a mobile aggregate crushing plant is, how it works, and the benefits of using one.

A mobile aggregate crushing plant is a specialized type of machinery that is used for crushing and processing rocks, stones, and other materials into aggregate for use in construction projects. The plant is designed to be compact, mobile, and easy to move, making it ideal for use on job sites where space is limited or where there is a need for materials to be crushed and processed on-site.

The process of crushing and processing aggregate involves several stages. The first stage involves the use of a primary crusher to break down the raw materials into smaller pieces. This is typically done using a jaw crusher, which is designed to handle large rocks and stones.

Once the raw materials have been broken down into smaller pieces, they are then transported to a secondary crusher. This crusher is designed to further reduce the size of the materials, making them suitable for use in construction projects.

Finally, the processed materials are screened to remove any debris or impurities, and the resulting aggregate is then ready for use in construction projects.

A mobile aggregate crushing plant works by first loading the raw materials into the hopper of the primary crusher. The raw materials are then fed into the crusher, where they are broken down into smaller pieces.

Once the raw materials have been broken down, they are then transported to the secondary crusher using a conveyor belt. The secondary crusher further reduces the size of the materials, making them suitable for use in construction projects.

After the materials have been crushed, they are then screened to remove any debris or impurities. The resulting aggregate is then ready for use in construction projects.

Our Projects

Copyright © ZENITH, All Right Reserved.