One of the essential processes in harnessing its potential is the crushing of feldspar rocks into smaller, more manageable sizes. A high-quality feldspar crushing plant comprises several key components that work together to ensure efficient and effective processing.

24 Online Service

Feldspar, an essential mineral found abundantly on Earth, plays a pivotal role in various industries, including ceramics, glass, and construction. Understanding the formation and processing of feldspar is crucial for unlocking its potential.

Feldspar, a group of rock-forming minerals, is predominantly composed of aluminum silicates combined with either potassium, sodium, or calcium. It is commonly found in igneous rocks, metamorphic rocks, and even some sedimentary rocks. The formation of feldspar begins during the crystallization of magma, the molten rock deep within the Earth’s crust. As magma cools and solidifies, feldspar minerals start to crystallize, taking different forms depending on the chemical composition of the magma.

Feldspar finds extensive applications in diverse industries due to its unique properties. Some notable applications include:

Once feldspar deposits are identified, mining operations commence to extract the mineral. Feldspar mining primarily involves two methods: open-pit mining and underground mining. Open-pit mining is commonly used when feldspar deposits are close to the surface, while underground mining is preferred for deeper deposits.

In open-pit mining, large machinery, such as excavators and bulldozers, is employed to remove overlying soil and rocks, exposing the feldspar deposit. The ore is then extracted using blasting techniques and transported to the processing plant for further refinement.

In underground mining, tunnels and shafts are created to access the feldspar deposit. Miners use drilling and blasting methods to extract the ore, which is then transported to the surface for processing.

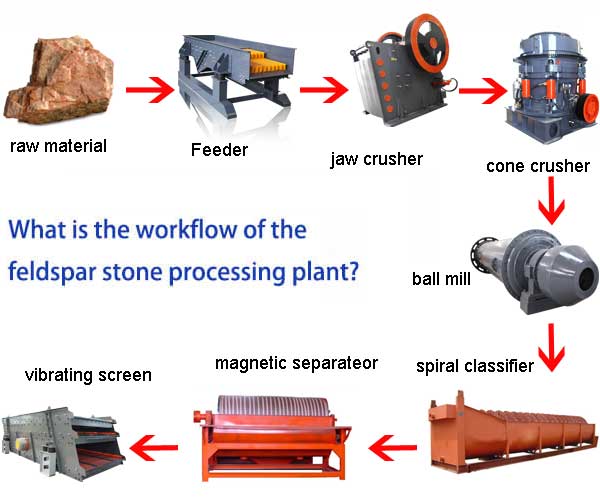

Once feldspar ore is obtained from mining operations, it undergoes several processing stages to refine it into a usable form. The processing steps typically include:

The beneficiation and flotation process offers numerous advantages in improving the quality and value of feldspar:

One of the essential processes in harnessing its potential is the crushing of feldspar rocks into smaller, more manageable sizes. A high-quality feldspar crushing plant comprises several key components that work together to ensure efficient and effective processing.

A feldspar crushing plant begins with the primary stage, where raw feldspar rocks are loaded into the vibrating feeder. The vibrating feeder is responsible for delivering a constant and controlled flow of rocks to the jaw crusher, ensuring a steady feed rate. It prevents overload and blockages in the crushing chamber, thus optimizing the plant’s productivity.

The jaw crusher is a primary crushing machine that plays a fundamental role in the feldspar crushing process. It is responsible for reducing the size of the raw feldspar rocks into smaller fragments. The design of the jaw crusher should be sturdy and robust to withstand the high pressure and force exerted during the crushing operation. Additionally, it should have a large feed opening and a high reduction ratio to ensure efficient crushing.

After the initial crushing stage, the feldspar fragments are further reduced in size by the cone crusher. The cone crusher operates on the principle of compression crushing, where the rocks are squeezed between a mantle and a concave. It is crucial to select a cone crusher with a high capacity and excellent crushing efficiency to achieve the desired product size.

The vibrating screen is a vital component in a feldspar crushing plant as it separates the crushed materials into different sizes. It ensures that only the desired particle sizes pass through for further processing, while oversized materials are sent back to the crushers for re-crushing. An efficient vibrating screen should have a large screening area, adjustable amplitude, and a high screening efficiency.

A well-designed conveyor system is essential for the smooth operation of a feldspar crushing plant. It transports the crushed feldspar materials from one processing stage to another, eliminating the need for manual handling and reducing the risk of material contamination or spillage. The conveyor system should be reliable, durable, and equipped with safety features to prevent accidents and ensure continuous production.

During the crushing process, fine particles and dust are generated, which can be hazardous to the health of workers and detrimental to the overall plant efficiency. A high-quality feldspar crushing plant incorporates a robust dust collection system to capture and remove airborne particles. It helps maintain a clean and safe working environment, minimizes equipment wear, and prevents product contamination.

To optimize the performance of a feldspar crushing plant, a well-designed control system is imperative. The control system should be user-friendly and capable of monitoring and adjusting various parameters such as feed rate, crusher settings, and conveyor speeds. It enables operators to fine-tune the plant’s operation, maximize productivity, and minimize downtime due to operational issues.

A reliable and efficient electrical system is crucial for the overall functioning of a feldspar crushing plant. It powers the motors of the crushers, screens, and conveyors, as well as other auxiliary equipment. The electrical system should be properly designed, well-maintained, and equipped with safety mechanisms to prevent electrical failures and ensure a smooth operation.

A high-quality feldspar crushing plant consists of several essential components that work together to efficiently process raw feldspar rocks into smaller, more manageable sizes.

With its versatile properties and abundance in the Earth’s crust, feldspar has become an essential component in many everyday products. When it comes to acquiring a feldspar crushing plant, selecting a high-quality and reliable one is of utmost importance.

One of the primary factors to consider is the efficiency and productivity of the feldspar crushing plant. A high-quality plant should be equipped with modern technology and machinery that can process feldspar efficiently. Look for features such as advanced crushing chambers, high crushing ratio, and optimized operational parameters. A plant with these characteristics will ensure maximum productivity and a consistent supply of high-quality feldspar.

Investing in a feldspar crushing plant is a long-term decision, and it is essential to choose a plant that is reliable and durable. Look for plants manufactured by reputable companies with a track record of delivering reliable equipment. Consider the quality of materials used in the construction of the plant and the robustness of its components. A well-built plant will have a longer lifespan, minimizing downtime and reducing the overall cost of ownership.

Every feldspar deposit is unique, and its processing requirements may vary. Therefore, it is crucial to choose a crushing plant that offers customization and flexibility. Look for a plant that can be easily adjusted to meet specific production needs. This includes the ability to modify crushing parameters, adjust feed sizes, and incorporate additional screening or sorting options. A flexible plant will allow you to optimize the processing of feldspar and adapt to changing market demands.

In today’s world, environmental sustainability is a significant concern. When selecting a feldspar crushing plant, it is important to choose a plant that meets environmental regulations and minimizes its impact on the surrounding ecosystem. Look for plants that are designed with advanced dust suppression systems, efficient water management, and noise reduction measures. Additionally, consider energy consumption and choose a plant that incorporates energy-saving features to reduce carbon footprint.

A reliable supplier should provide excellent after-sales service and support. Ensure that the manufacturer or supplier has a strong reputation for customer service and technical assistance. This includes prompt response to inquiries, availability of spare parts, and on-site support when needed. A comprehensive after-sales service ensures that any potential issues with the plant can be addressed quickly, minimizing downtime and maximizing productivity.

While considering all the aforementioned factors, it is important to evaluate the cost and expected return on investment (ROI) of the feldspar crushing plant. Compare prices and specifications from different suppliers and manufacturers. Look for a plant that offers a good balance between initial investment cost and long-term operational efficiency. Consider the plant’s expected lifespan, maintenance requirements, and the quality of the final product it can deliver. A well-informed investment decision will lead to a higher ROI in the long run.

Choosing a high-quality feldspar crushing plant requires careful consideration of several key factors. Efficiency, reliability, customization, and environmental considerations should be at the forefront of the decision-making process. Additionally, after-sales service and support, as well as cost-effectiveness, are crucial elements to evaluate. By taking all these factors into account, you can ensure that your investment in a feldspar crushing plant will result in increased productivity, high-quality feldspar, and long-term operational success.

Raw Material:Feldspar

Capacity:200-250TPH

Input Size: 0-5mm

Equipment:PE750 deep cavity heavy jaw crusher (1 set), HPT300 multi cylinder hydraulic cone crusher (1 set), PFW1315III European hydraulic three cavity impact crusher (1 set)

Our Projects

Copyright © ZENITH, All Right Reserved.