Quartz is a mineral composed of silicon and oxygen atoms, with the chemical formula SiO2. It is one of the most abundant minerals on Earth and can be found in many types of rocks, including igneous, metamorphic, and sedimentary rocks.

24 Online Service

There are many different varieties of quartz, each with its own unique properties and characteristics. Some of the most common varieties include amethyst, citrine, rose quartz, and smoky quartz.

Quartz powder is a finely ground mineral composed of silicon dioxide (SiO2), also known as silica. It is one of the most abundant minerals found on Earth and is found in many types of rocks, including granite, sandstone, and quartzite.

Quartz powder has a wide range of uses, including as a raw material for glass production, in the manufacturing of ceramics, as a filler for rubber and plastics, in paint and coatings, and as an abrasive in various industrial processes. It is also used in the construction industry as an additive to concrete and other building materials.

Quartz powder is usually produced by grinding quartz crystals or silica-rich rock formations into a fine powder. The powder can range in color from white to gray, depending on the source material and the degree of processing. It is generally considered to be a safe and non-toxic substance, although prolonged exposure to high concentrations of airborne silica dust can be harmful to human health.

Quartz is a mineral that is found in abundance on the earth’s crust. It is a durable, hard, and versatile mineral that has been used by humans for centuries. Quartz is used in various fields such as electronics, jewelry, and construction.

Quartz is a mineral composed of silicon dioxide (SiO2). It is one of the most abundant minerals found on earth, and it is found in almost every rock type. The purest form of quartz is colorless, but it can also be found in various colors such as pink, purple, brown, black, and green.

One of the most common uses of quartz is in the manufacturing of electronics. Quartz crystals are used in electronic devices such as watches, radios, and computers. Quartz is an excellent conductor of electricity and is used in electronic circuits to provide a precise timing reference. Quartz oscillators are used in clocks and watches to keep time accurately.

Quartz is also used in the construction industry. It is a durable and hard mineral that can withstand extreme weather conditions. Quartz is used in the manufacturing of concrete, which is a primary building material. Quartz sand is added to concrete to increase its strength and durability. Quartz is also used as a decorative stone in construction projects. It is often used as a flooring material, and it is also used as a countertop material in kitchens and bathrooms.

Another use of quartz is in the manufacturing of glass. Quartz is a major component of glass, and it is used to make glass products such as mirrors, windows, and lenses. Quartz is a hard and durable mineral that can withstand high temperatures, making it an ideal material for making glass.

Quartz is also used in the jewelry industry. Quartz crystals are used in the manufacturing of jewelry, and they are popular among jewelry designers because of their unique colors and shapes. Some of the most popular varieties of quartz used in jewelry making include amethyst, citrine, rose quartz, and smoky quartz.

Quartz is also used in alternative medicine and healing practices. It is believed that quartz has healing properties and can be used to balance the body’s energy. Quartz crystals are often used in meditation practices, and they are believed to enhance spiritual awareness and promote emotional healing.

In addition to its physical and practical uses, quartz also has spiritual and metaphysical significance. It is believed that quartz crystals can absorb, store, and release energy. Quartz is often used in crystal healing practices, and it is believed that different varieties of quartz have different healing properties. For example, amethyst is believed to promote calmness and reduce anxiety, while rose quartz is believed to promote love and emotional healing.

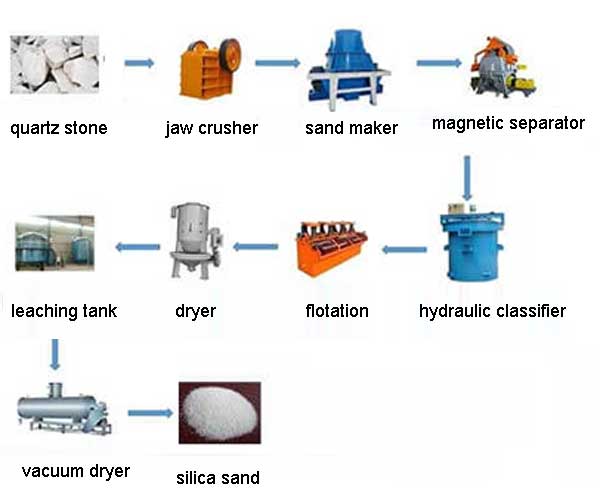

Quartz is a widely used mineral in industries such as glass, ceramics, and electronics. It is also a popular decorative stone used in jewelry and construction. However, before it can be used in these applications, it must undergo a manufacturing process to crush, refine and process the quartz crystals into various grades and sizes.

The quartz crushing manufacturing process is a complex and demanding operation that requires specialized equipment and skilled workers. This article will outline the steps involved in the quartz crushing manufacturing process and the importance of each step in the overall process.

The first step in the quartz crushing manufacturing process is to extract the raw quartz from the quarry. The quartz is extracted using heavy machinery, such as excavators and front-end loaders, which are used to remove the overburden and expose the quartz veins.

Once the quartz veins are exposed, the quartz is drilled and blasted using explosives. The quartz is then loaded onto trucks and transported to the crushing plant.

Once the raw quartz has been extracted from the quarry, it is transported to the crushing plant. Here, the quartz is crushed and ground into a fine powder using a series of crushers and mills.

The first stage of crushing involves the use of a primary crusher, which reduces the size of the quartz to a manageable size. The crushed quartz is then transported to a secondary crusher, which further reduces the size of the quartz to a fine powder.

Once the quartz has been crushed, it is then ground using a series of grinding mills. The grinding process is essential to achieve the desired size and consistency of the quartz powder.

After the quartz has been crushed and ground, it is then purified and refined to remove any impurities. The refining process involves washing the quartz powder with water and filtering out any impurities using various methods, such as gravity separation or flotation.

The quartz is then subjected to a process called leaching, which involves the use of chemicals to remove any remaining impurities. The leaching process may involve the use of hydrofluoric acid, which is highly corrosive and requires specialized equipment and training to handle safely.

Once the quartz has been purified and refined, it is then dried and sized to the required specifications. The drying process involves heating the quartz powder to remove any residual moisture. The quartz is then sieved and sorted to achieve the desired size and consistency.

The final step in the quartz crushing manufacturing process is packaging and shipping. The quartz powder is packaged in bags or containers and labeled according to its grade and size. The packaged quartz is then shipped to various industries and customers around the world.

Quartz is one of the hardest minerals on earth and requires specialized equipment to be crushed and processed into usable material.

The first machine required for quartz crushing is a crusher. There are several types of crushers that are used for quartz crushing. The most common ones are jaw crusher, cone crusher, and impact crusher. Jaw crushers are used for coarse and medium crushing, cone crushers for medium and fine crushing, and impact crushers for fine crushing. The choice of crusher depends on the size and shape of the quartz particles and the desired end product.

The first stage in quartz crushing and processing is the extraction of raw quartz materials from the ground. Quartz is typically found in igneous, metamorphic, and sedimentary rocks, and it is often mined from open-pit quarries. The extracted raw quartz materials are then transported to a processing plant where they are prepared for further processing.

The second stage in quartz crushing and processing is the primary crushing process, which typically involves jaw crushers. The quartz materials are fed into the jaw crusher machine where they are crushed to a size suitable for the secondary crushing process. The crushed quartz materials are then transported to a secondary crusher where they are further reduced in size.

The third stage in quartz crushing and processing is the secondary crushing process, which typically involves cone crushers or impact crushers. The secondary crusher breaks the quartz materials into even smaller sizes suitable for the subsequent stages of processing.

Once the quartz is crushed, it needs to be screened to separate the different sizes of particles. This is done using a vibrating screen. The vibrating screen is an important machine in the quartz crushing manufacturing process as it ensures that the particles are of the desired size and are uniform in shape.

The fourth stage in quartz crushing and processing is the screening process, where the quartz materials are separated into different sizes. The quartz materials are passed through a series of vibrating screens, where they are sorted according to their size. This stage is critical because it determines the quality of the final product.

The next machine required for quartz crushing is a grinding machine. The grinding machine is used to grind the crushed quartz particles into a fine powder. This is important as the powder is used in many industrial applications such as the production of glass and ceramics. There are several types of grinding machines used for quartz crushing, including ball mills, hammer mills, and vertical mills.

The fifth and final stage in quartz crushing and processing is the grinding process, where the quartz materials are ground into a fine powder. The grinding process typically involves ball mills or other types of grinding machines. The ground quartz powder is then washed and dried to remove any impurities and to produce a high-quality product suitable for various applications.

After the quartz particles have been ground into a fine powder, they need to be purified. This is done using a magnetic separator. The magnetic separator is an important machine in the quartz crushing manufacturing process as it removes any impurities from the powder. This ensures that the end product is of high quality and suitable for industrial use.

The final machine required for quartz crushing is a dryer. The dryer is used to dry the purified quartz powder. This is important as the powder needs to be completely dry before it can be packaged and transported. There are several types of dryers used for quartz crushing, including rotary dryers, fluidized bed dryers, and flash dryers.

In addition to the machines mentioned above, there are several other machines that may be required for the quartz crushing manufacturing process. These include conveyors, feeders, and storage tanks. Conveyors are used to transport the quartz particles between machines, feeders are used to control the flow of material into the machines, and storage tanks are used to store the purified quartz powder before it is packaged and transported.

Our Projects

Copyright © ZENITH, All Right Reserved.